Loadex

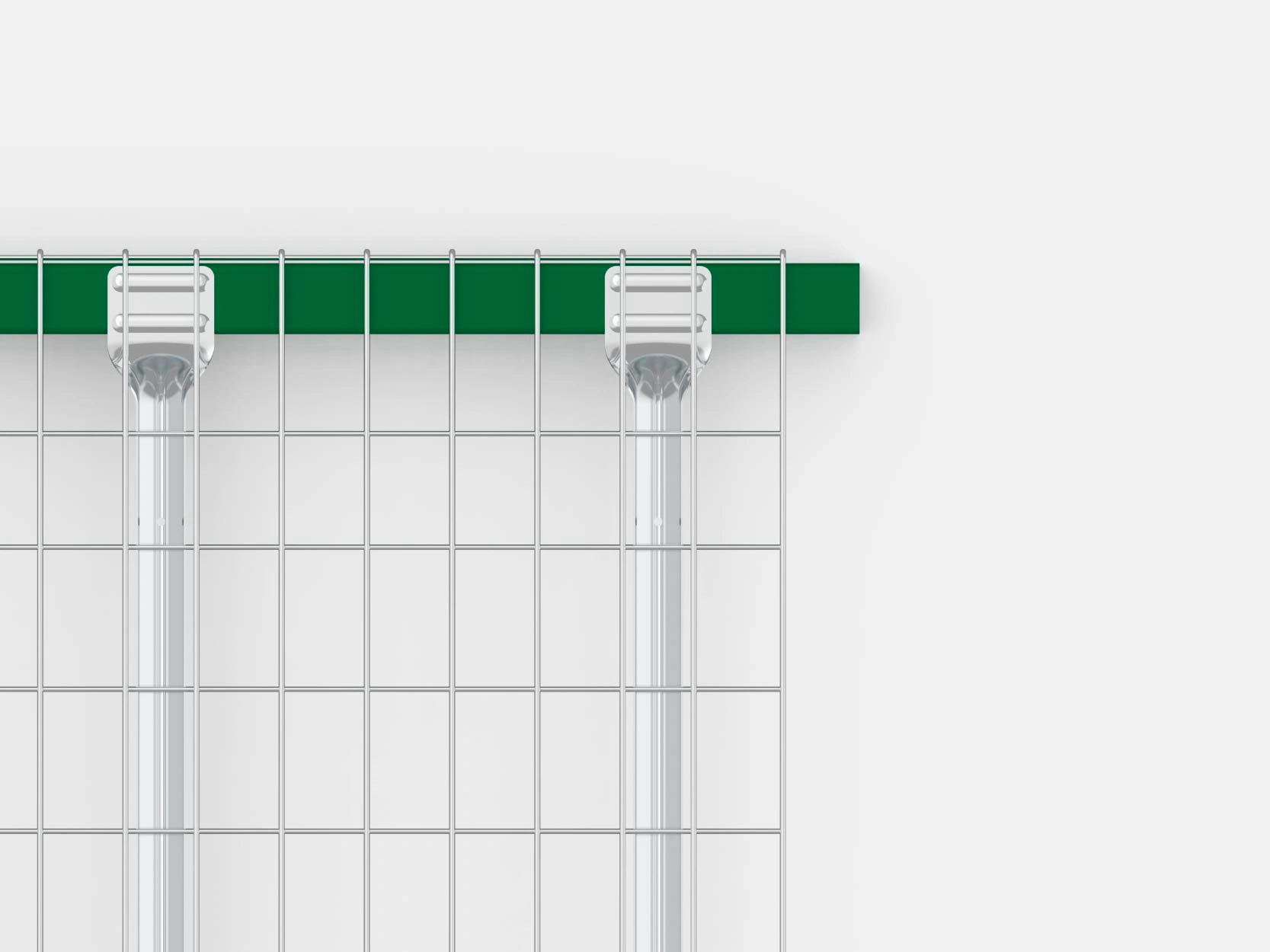

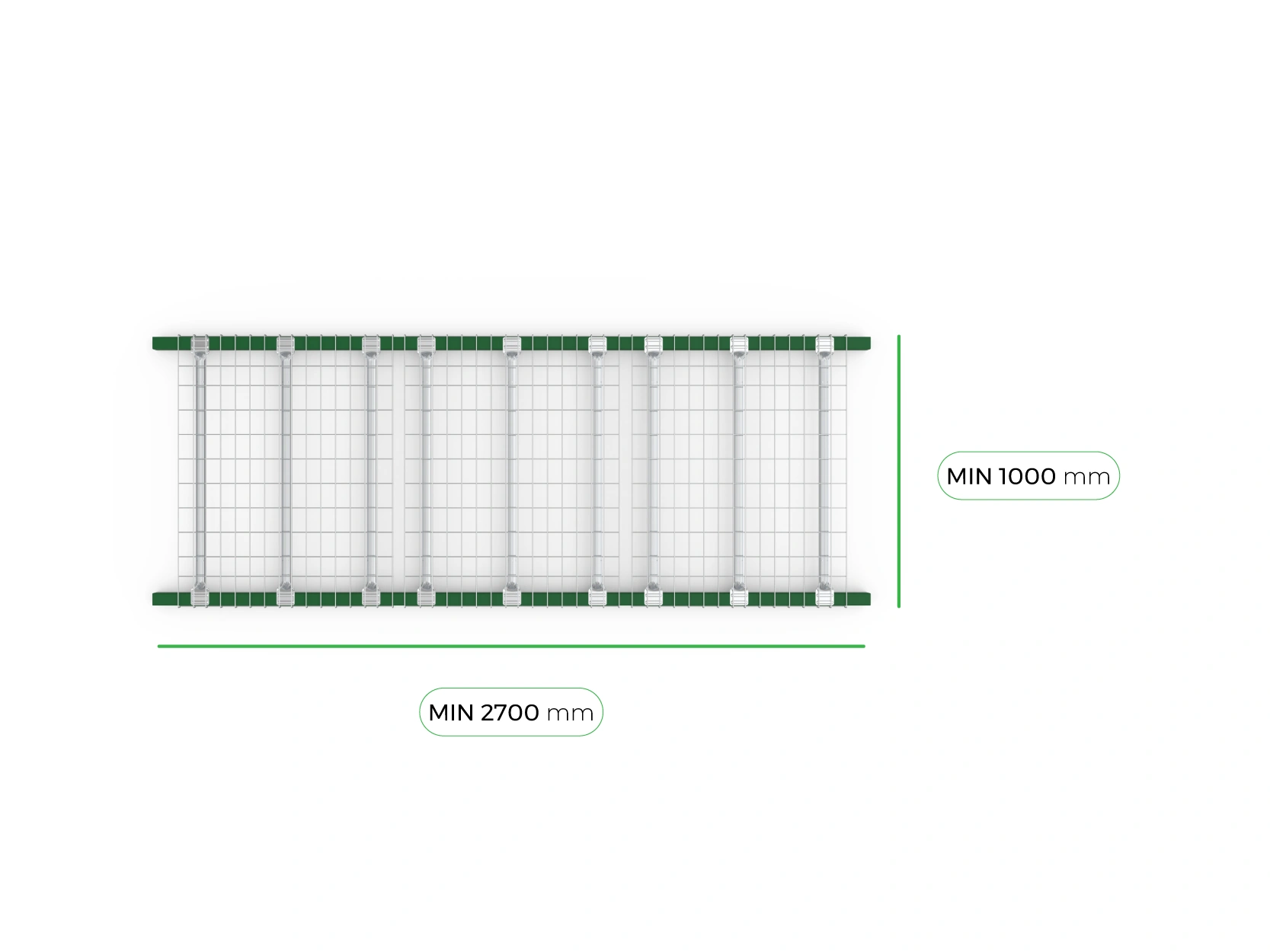

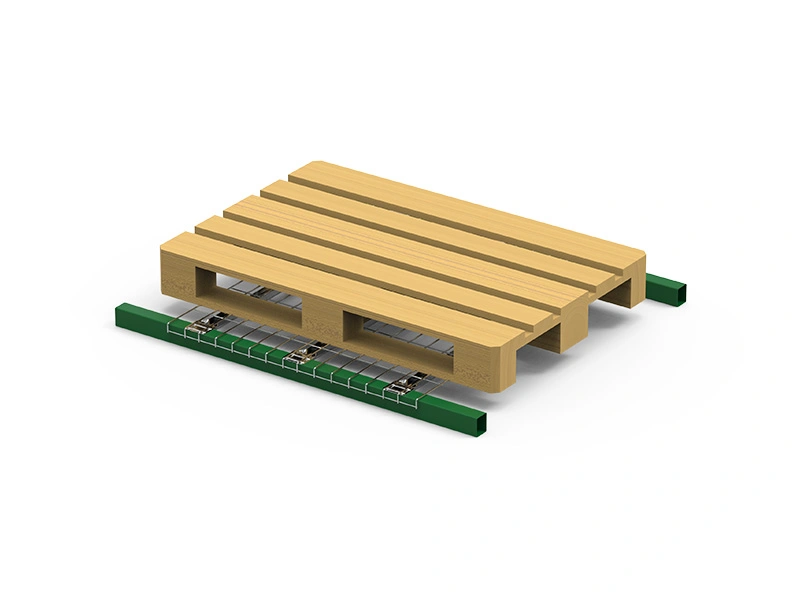

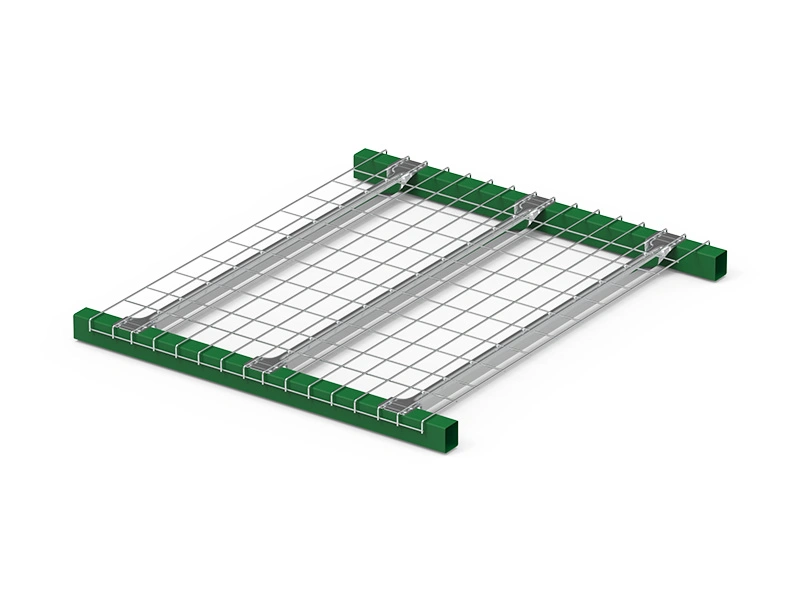

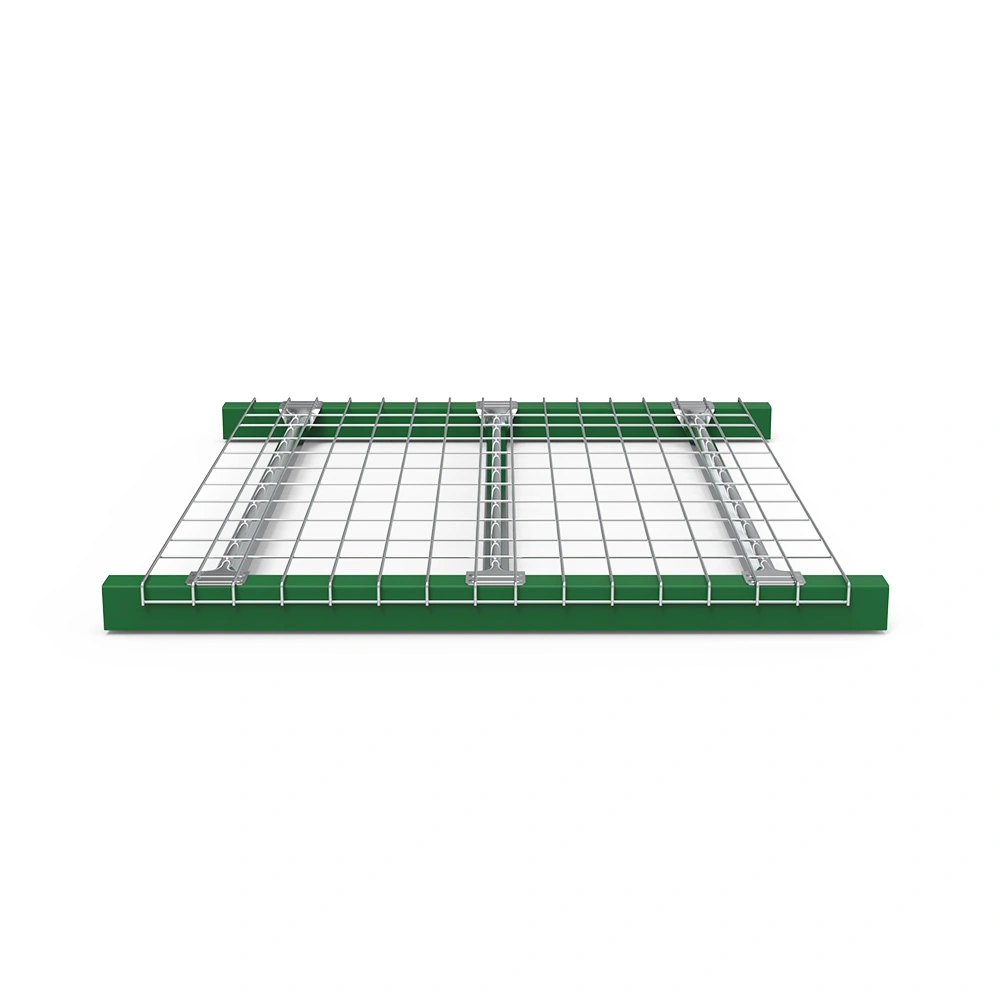

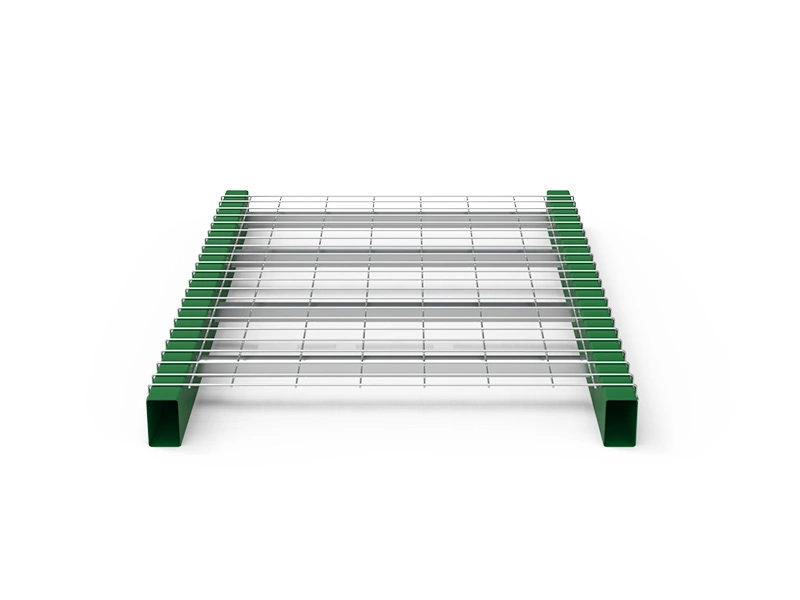

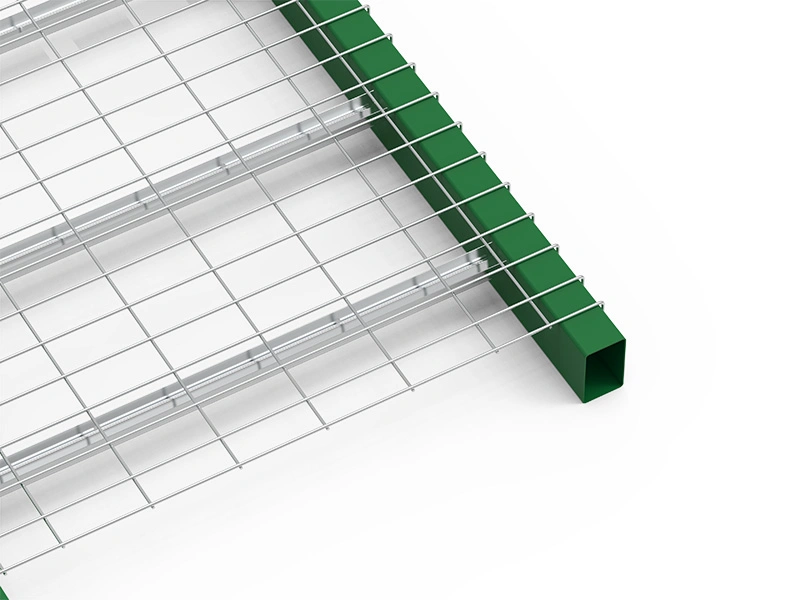

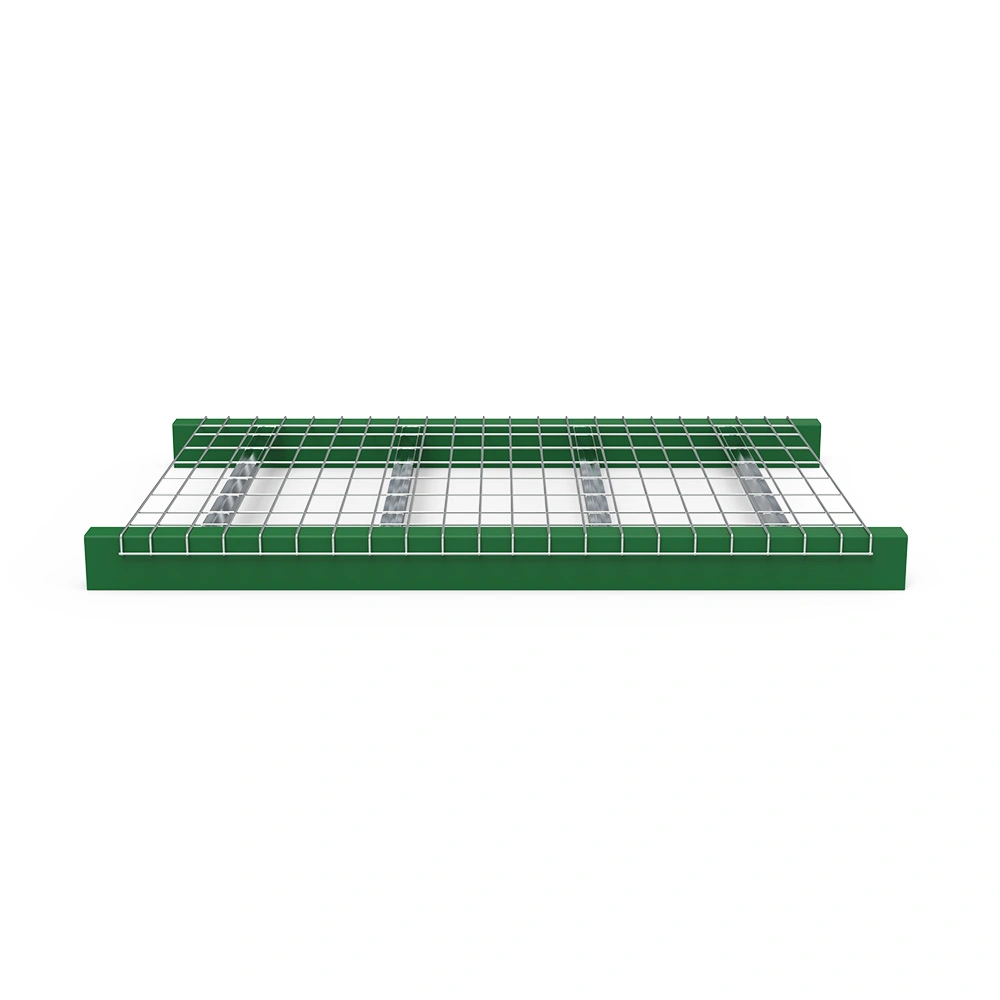

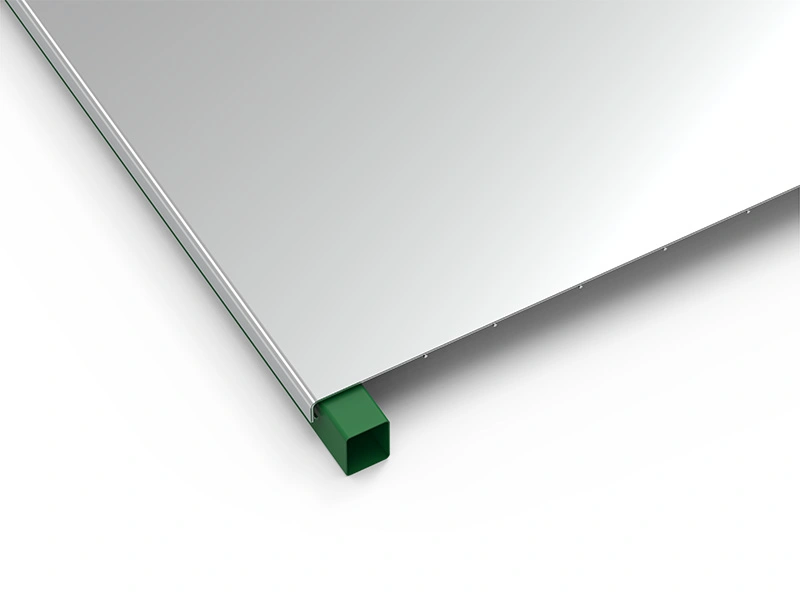

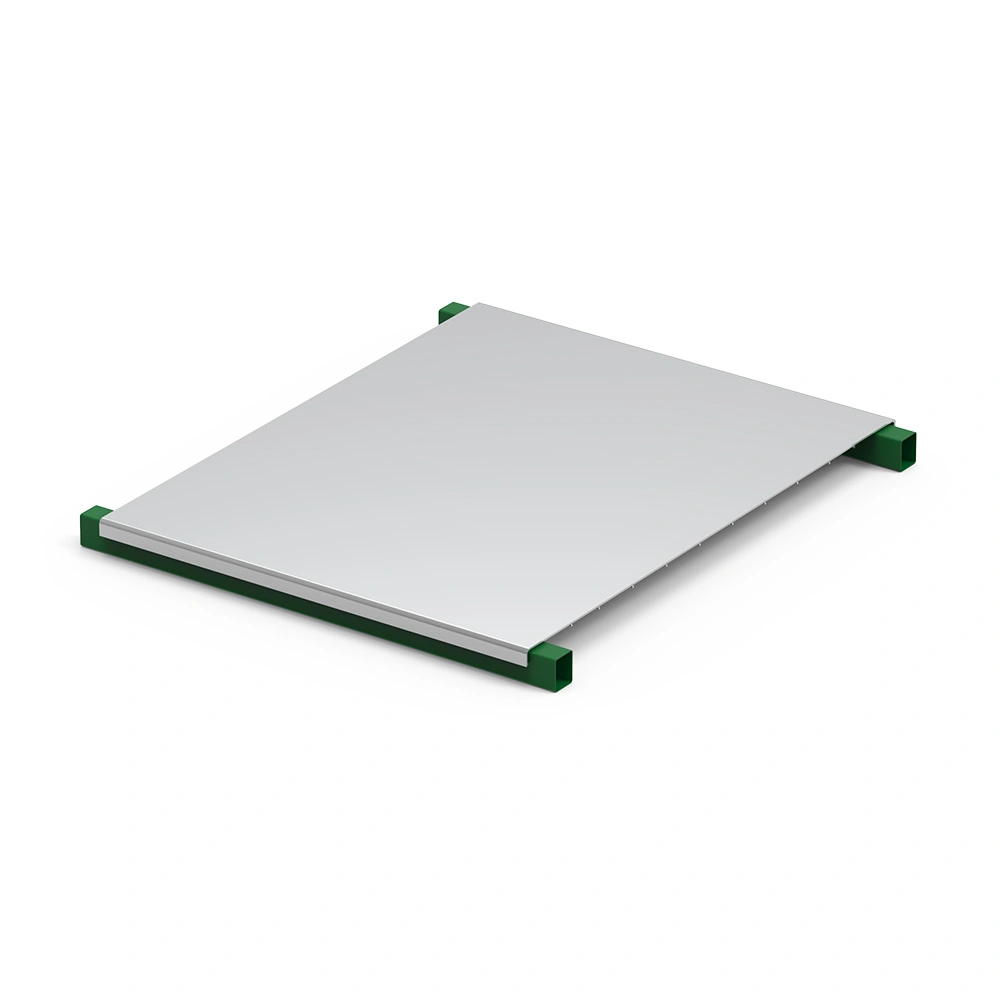

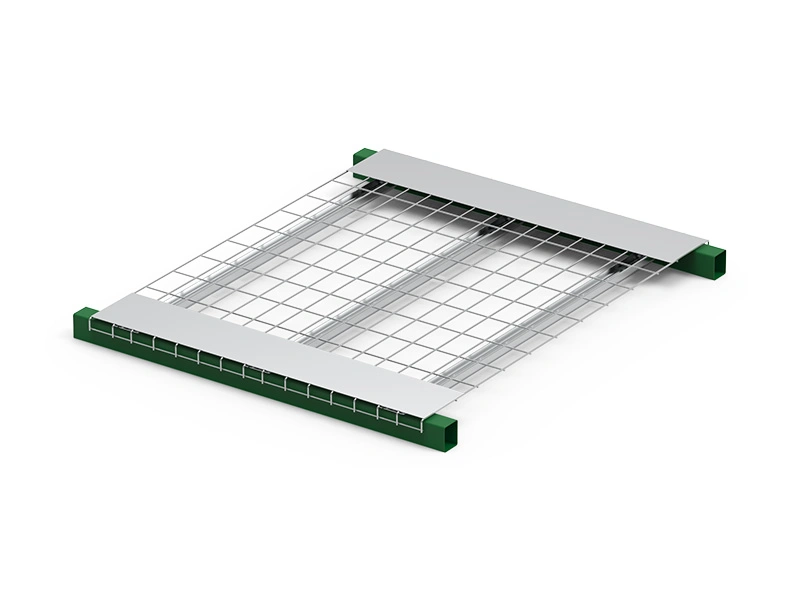

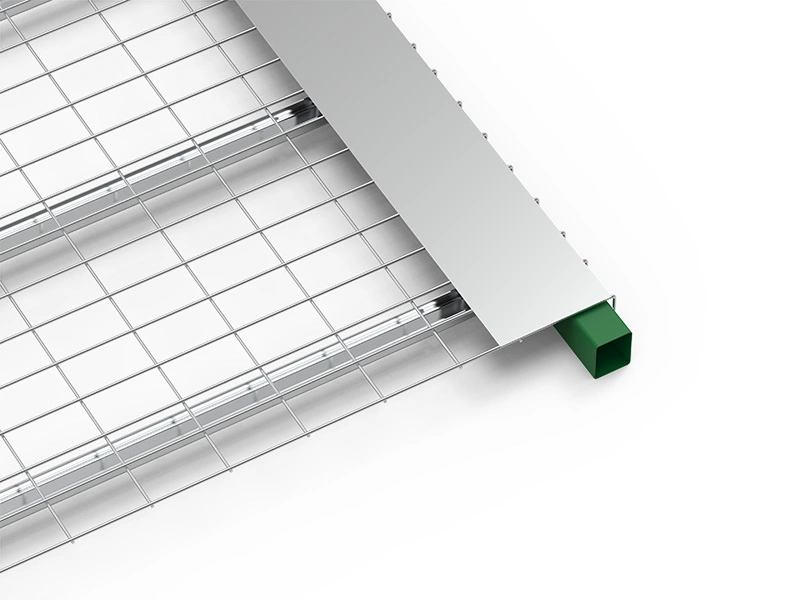

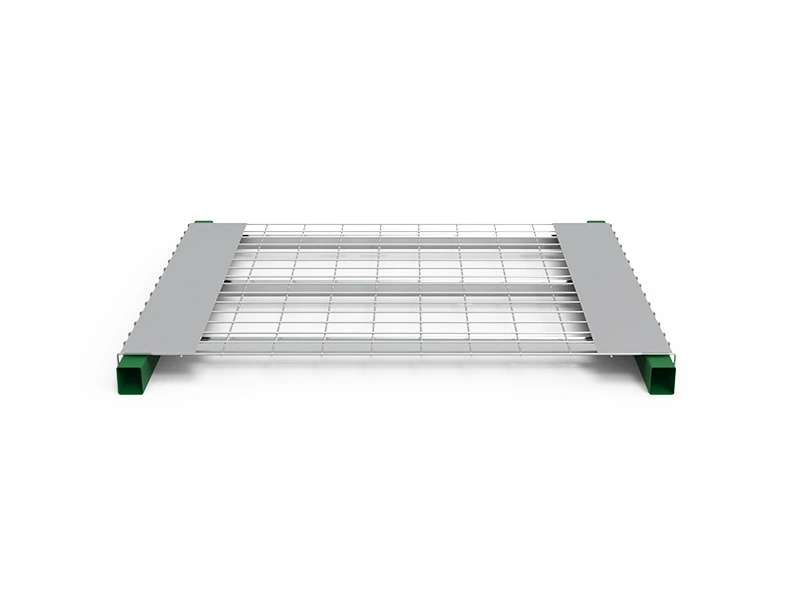

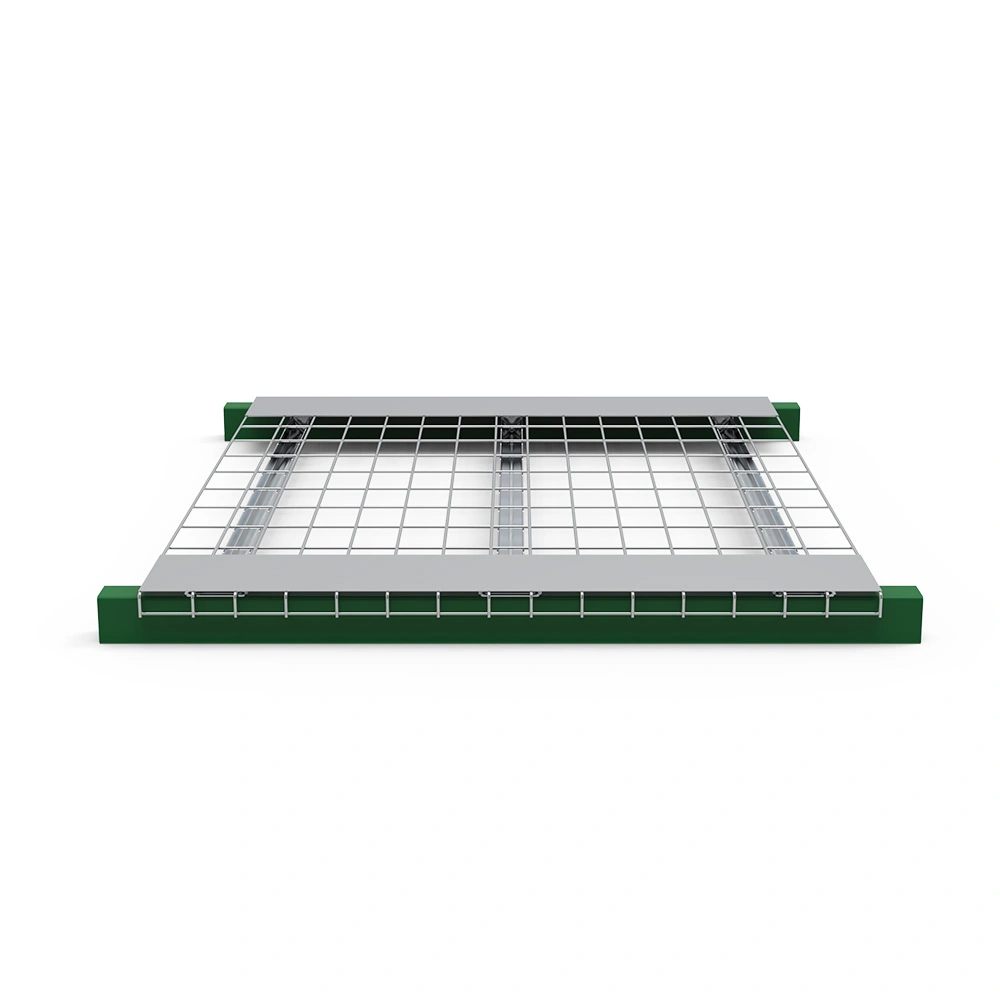

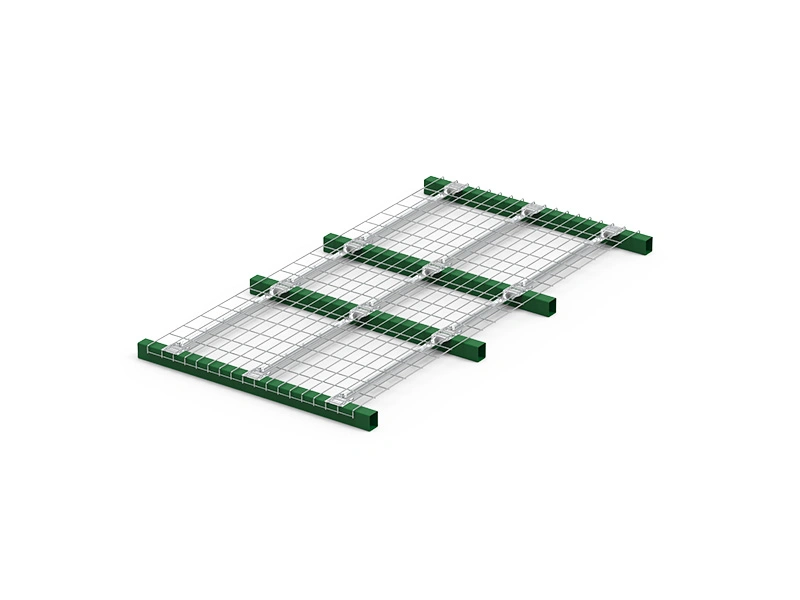

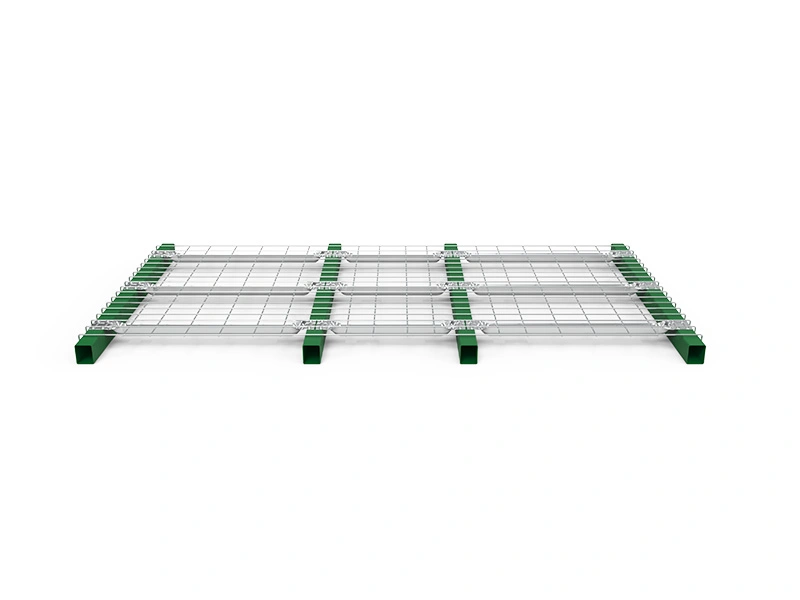

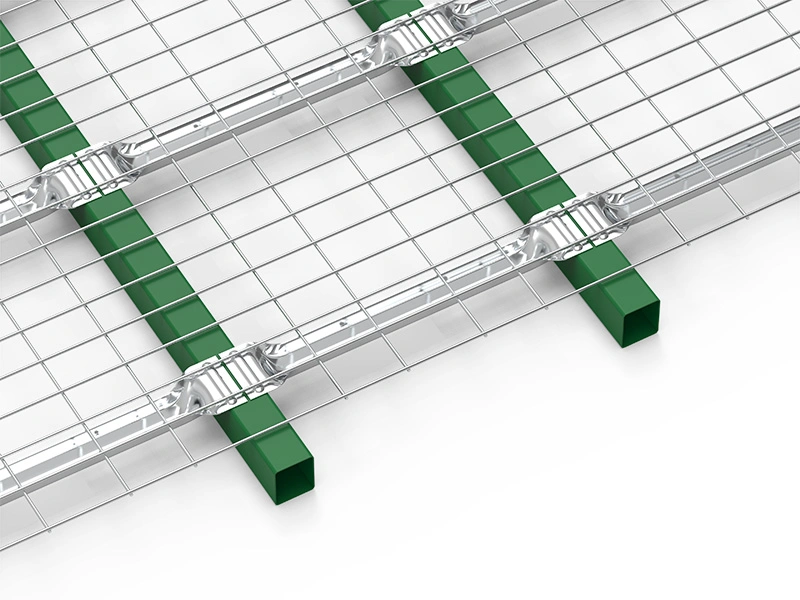

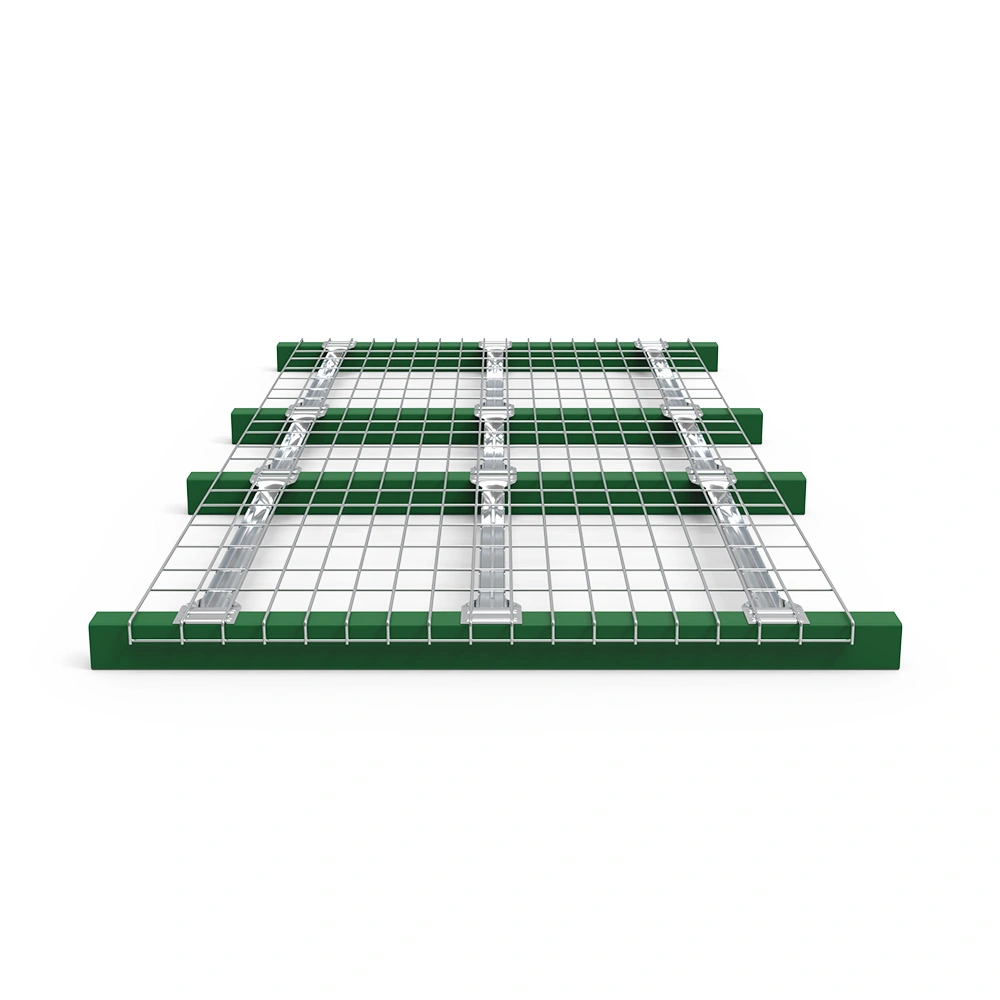

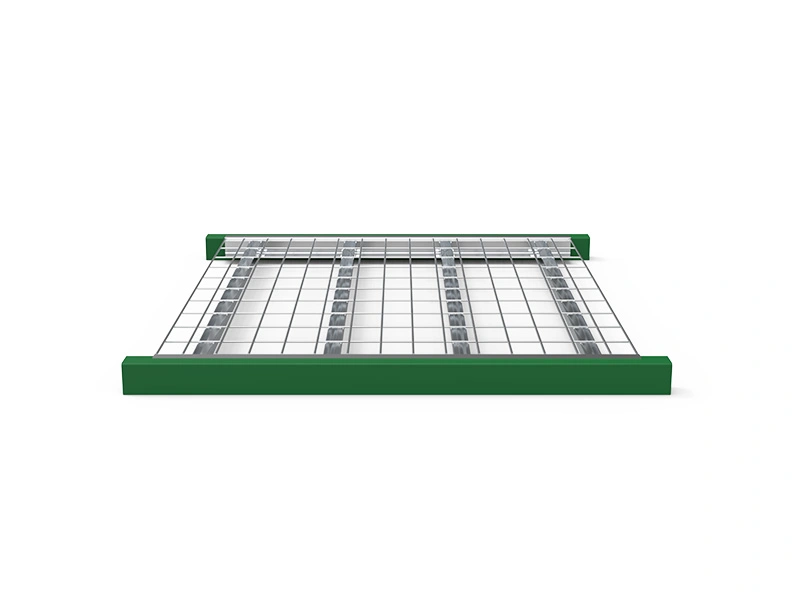

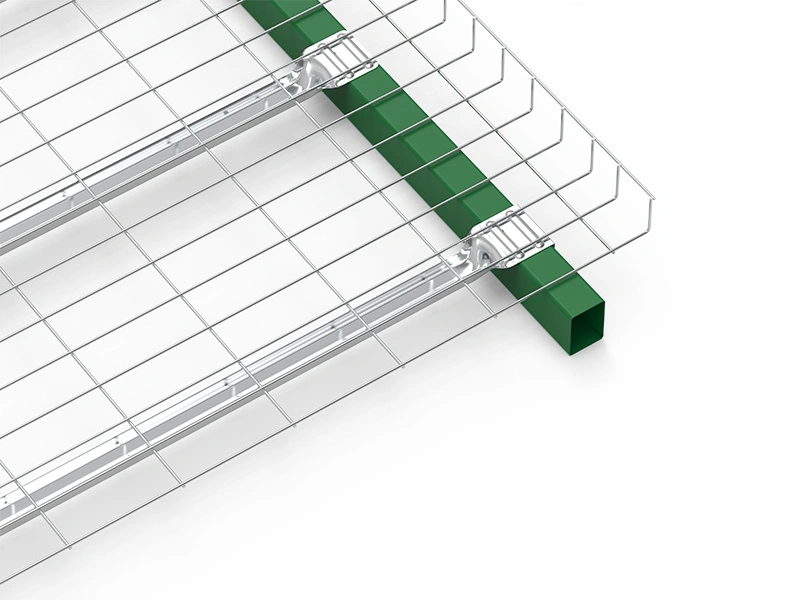

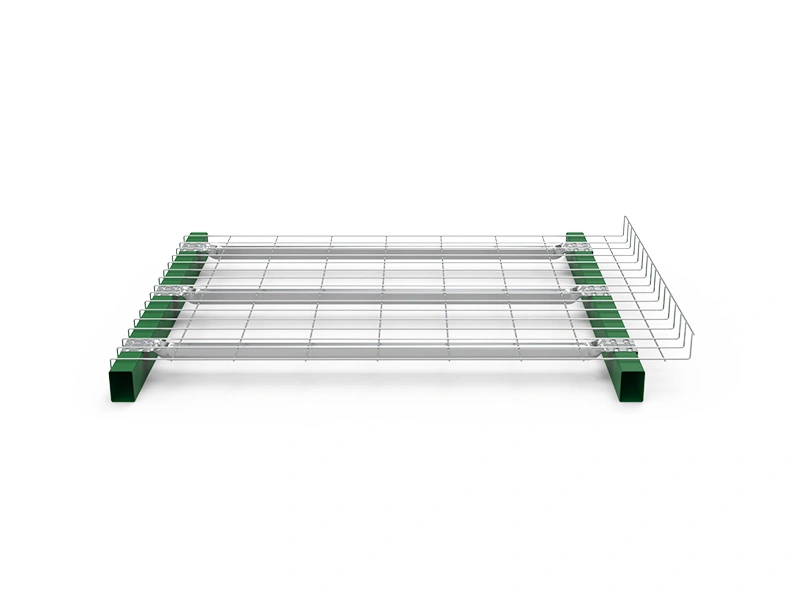

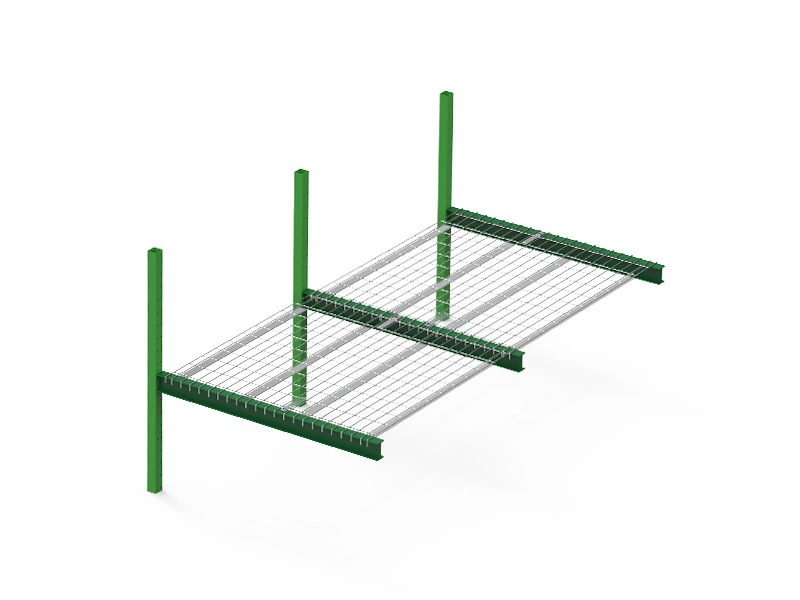

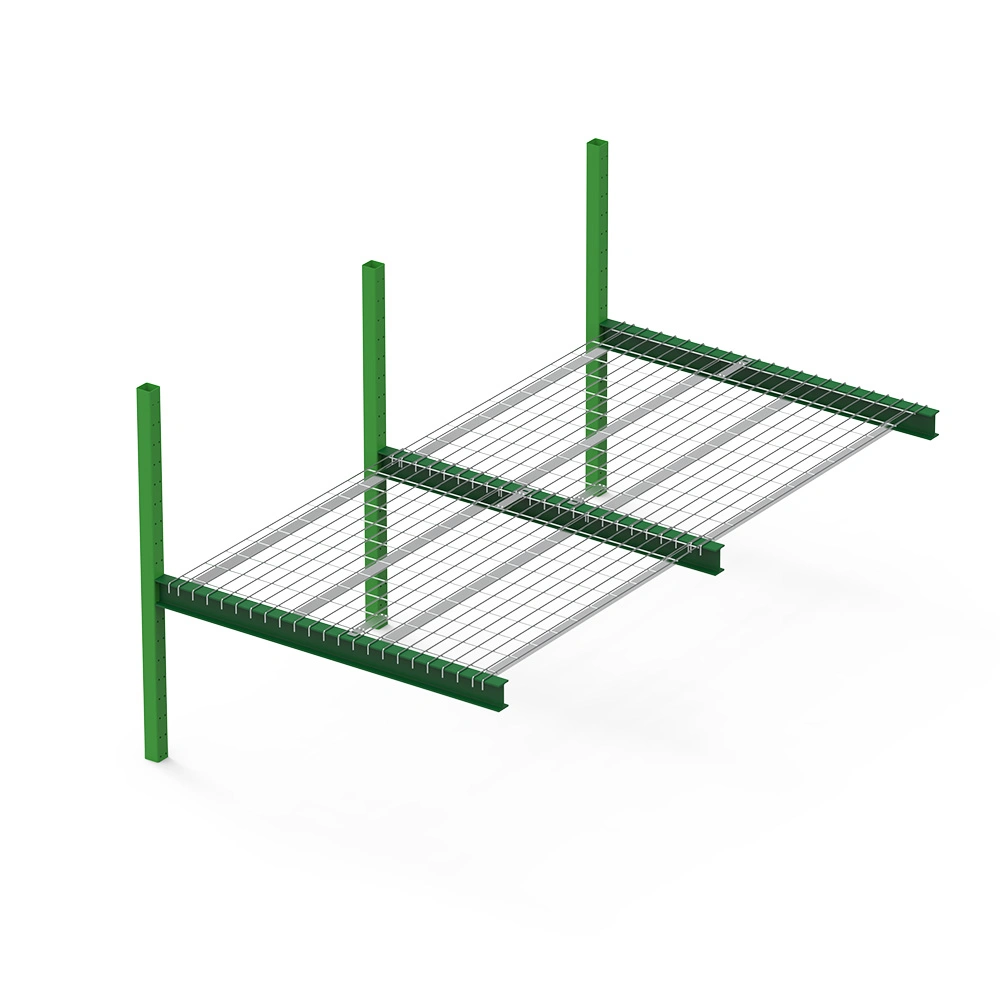

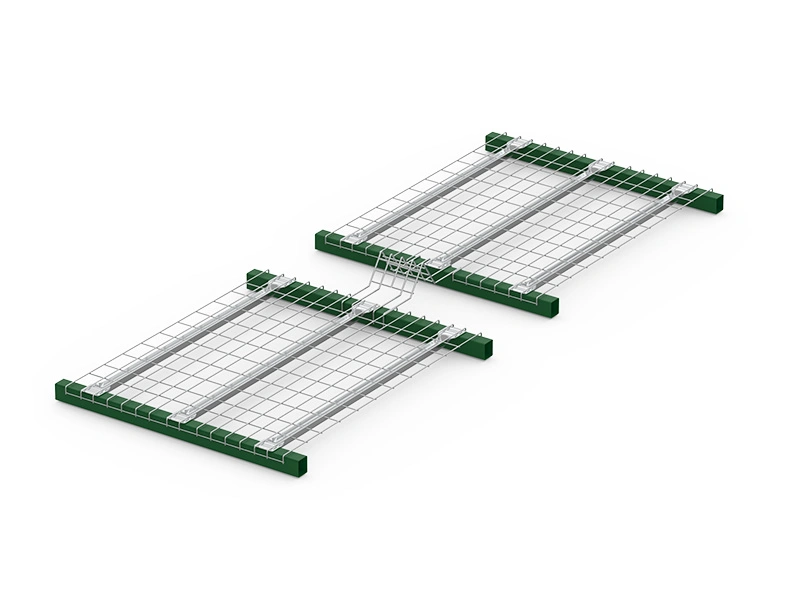

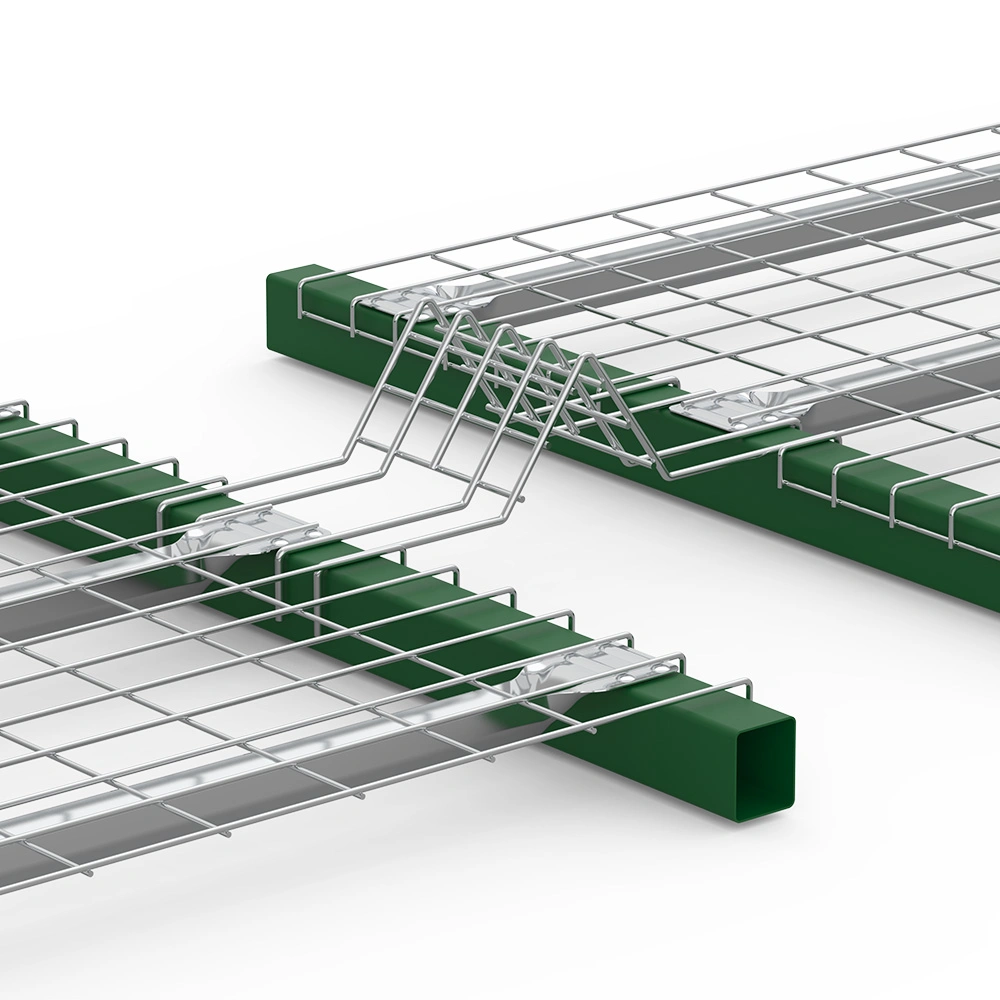

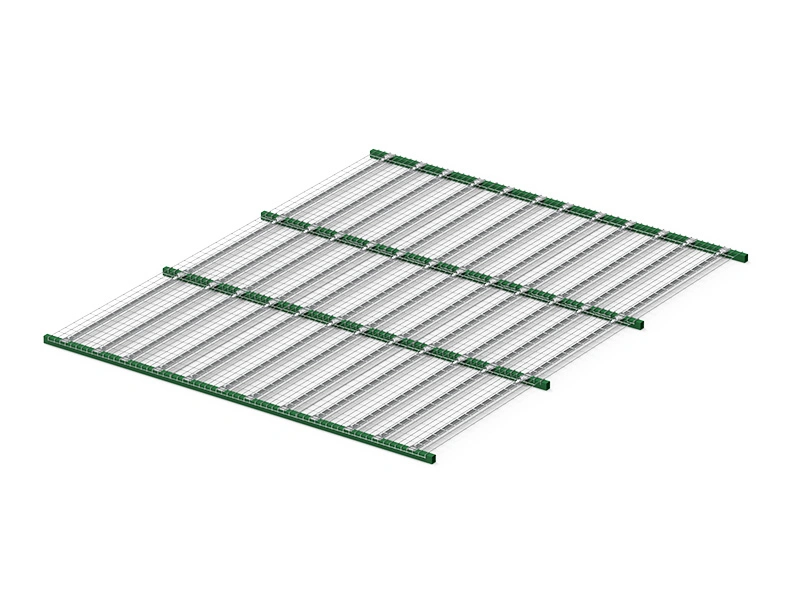

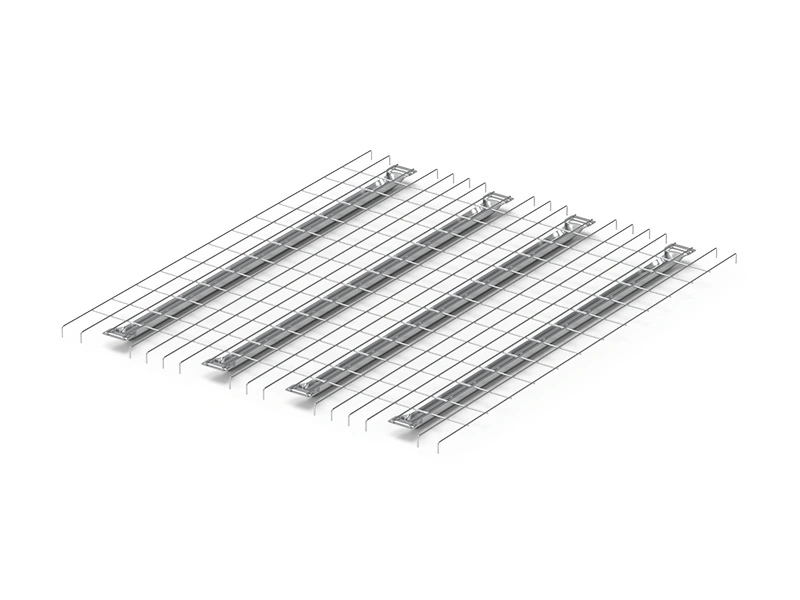

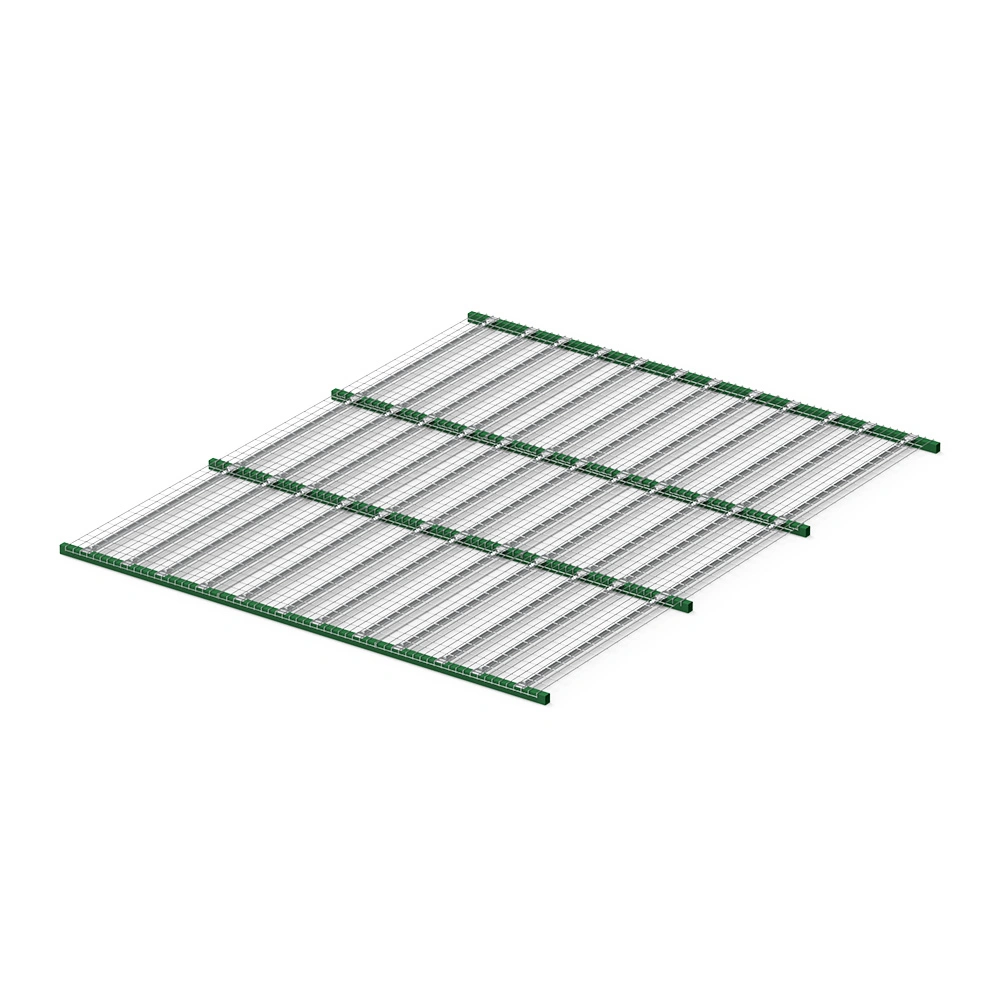

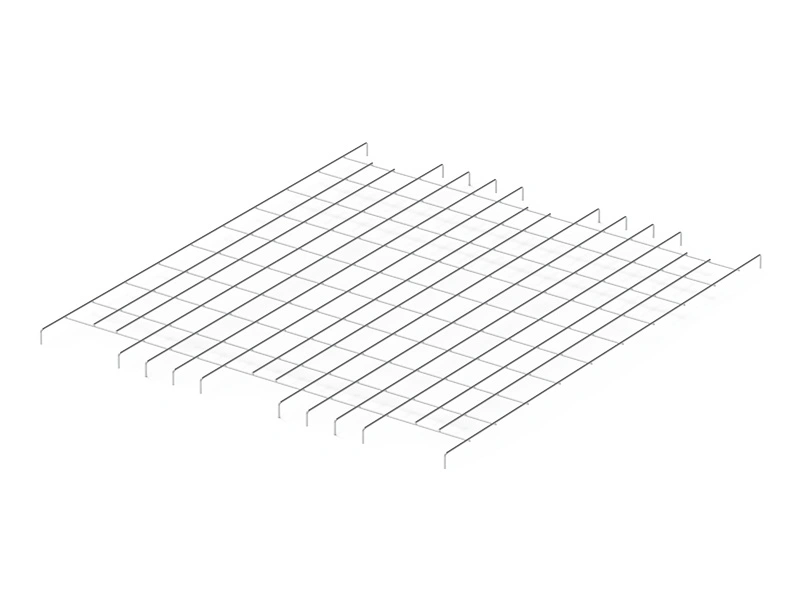

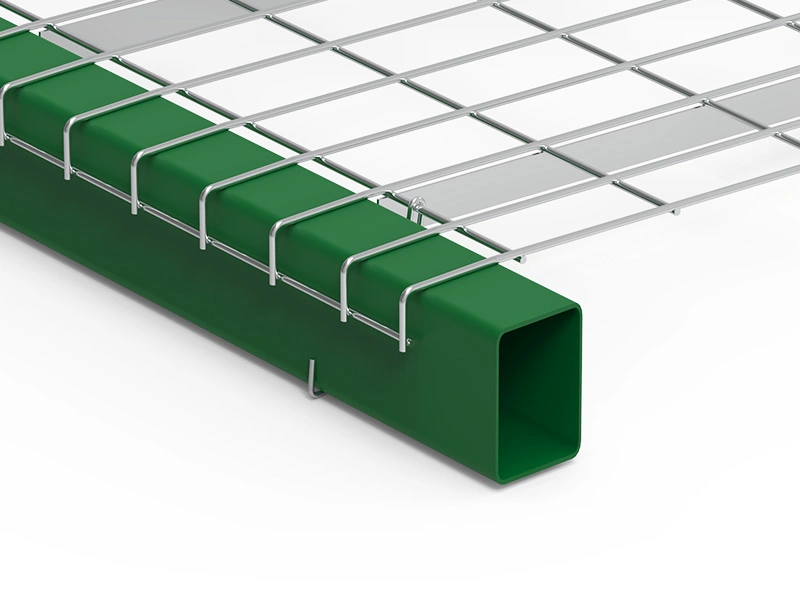

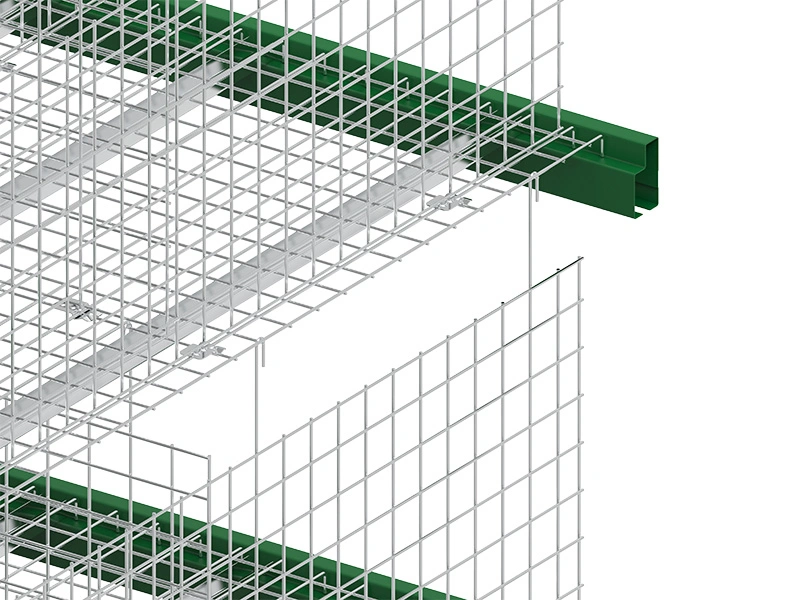

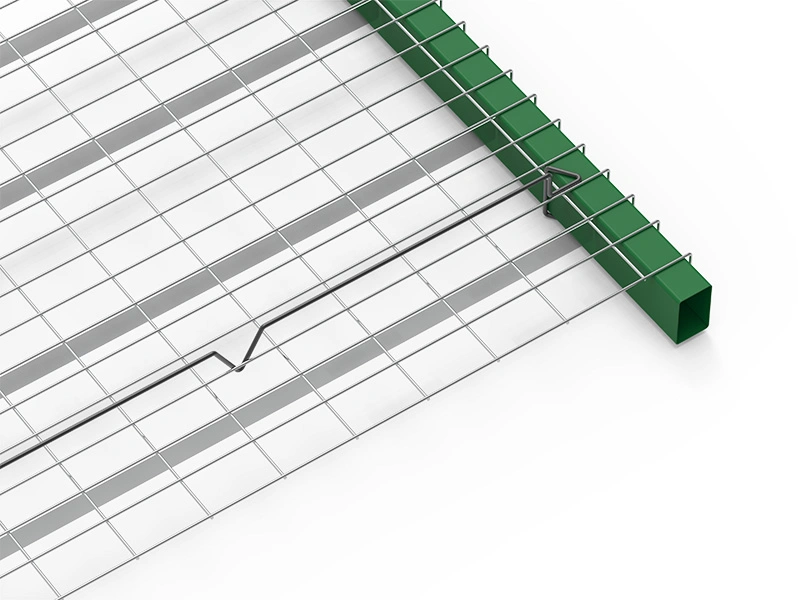

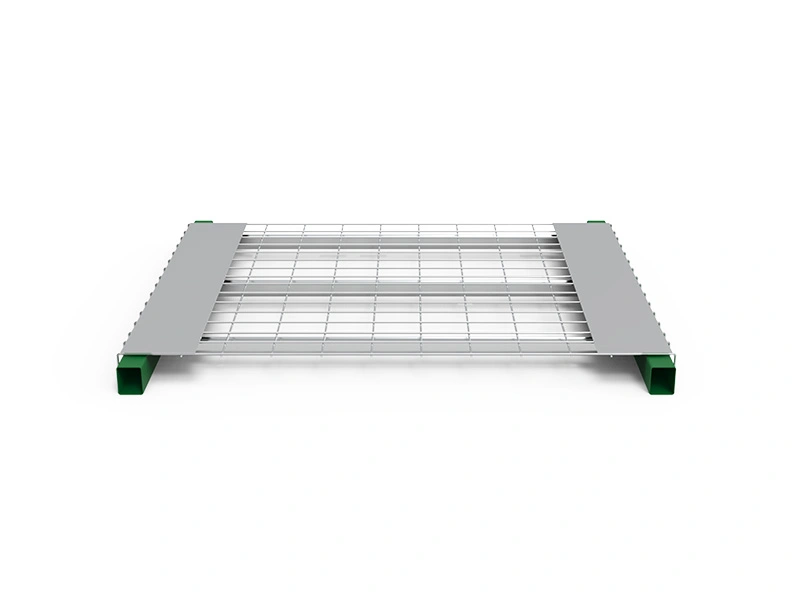

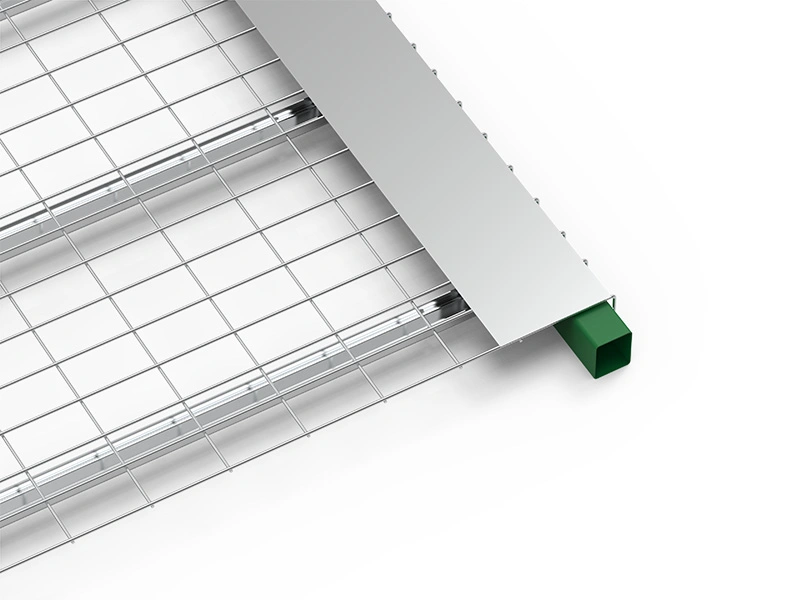

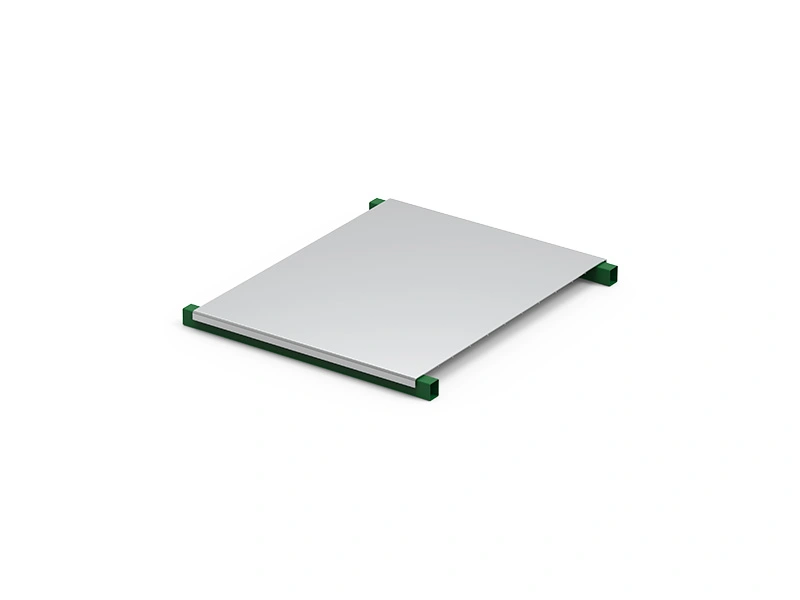

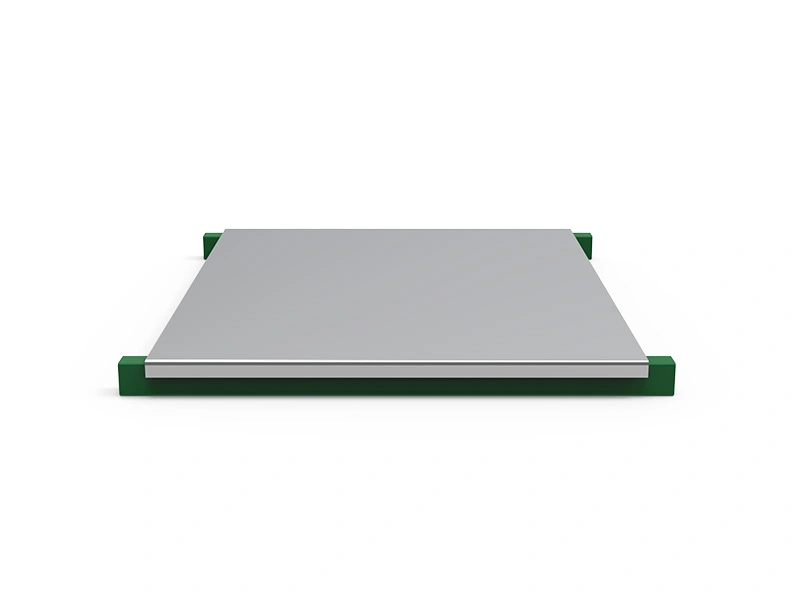

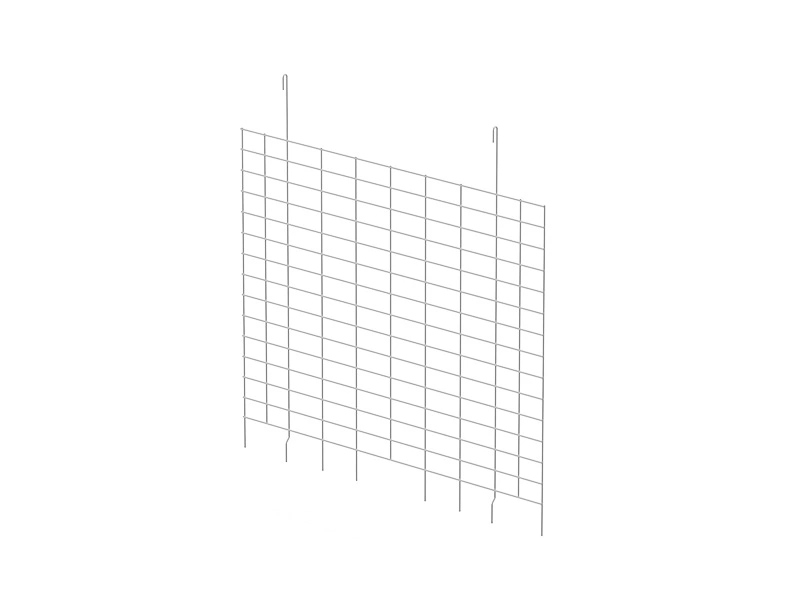

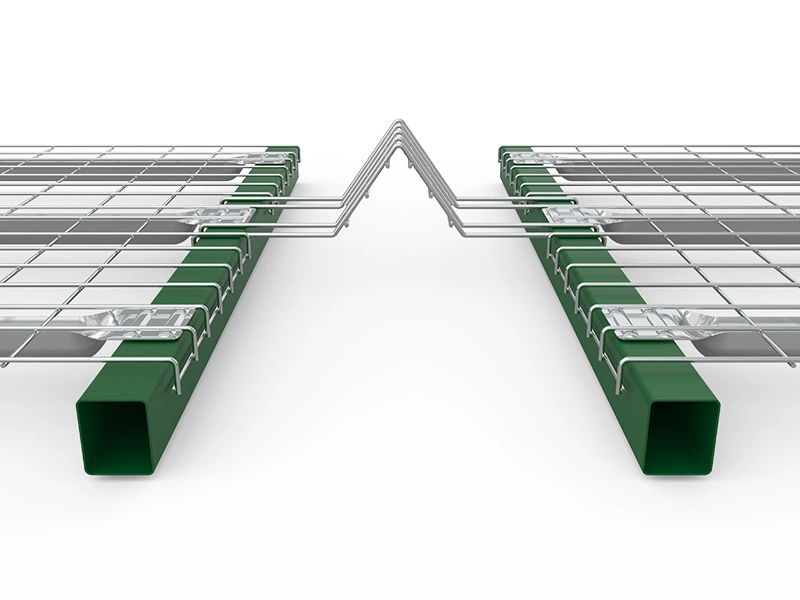

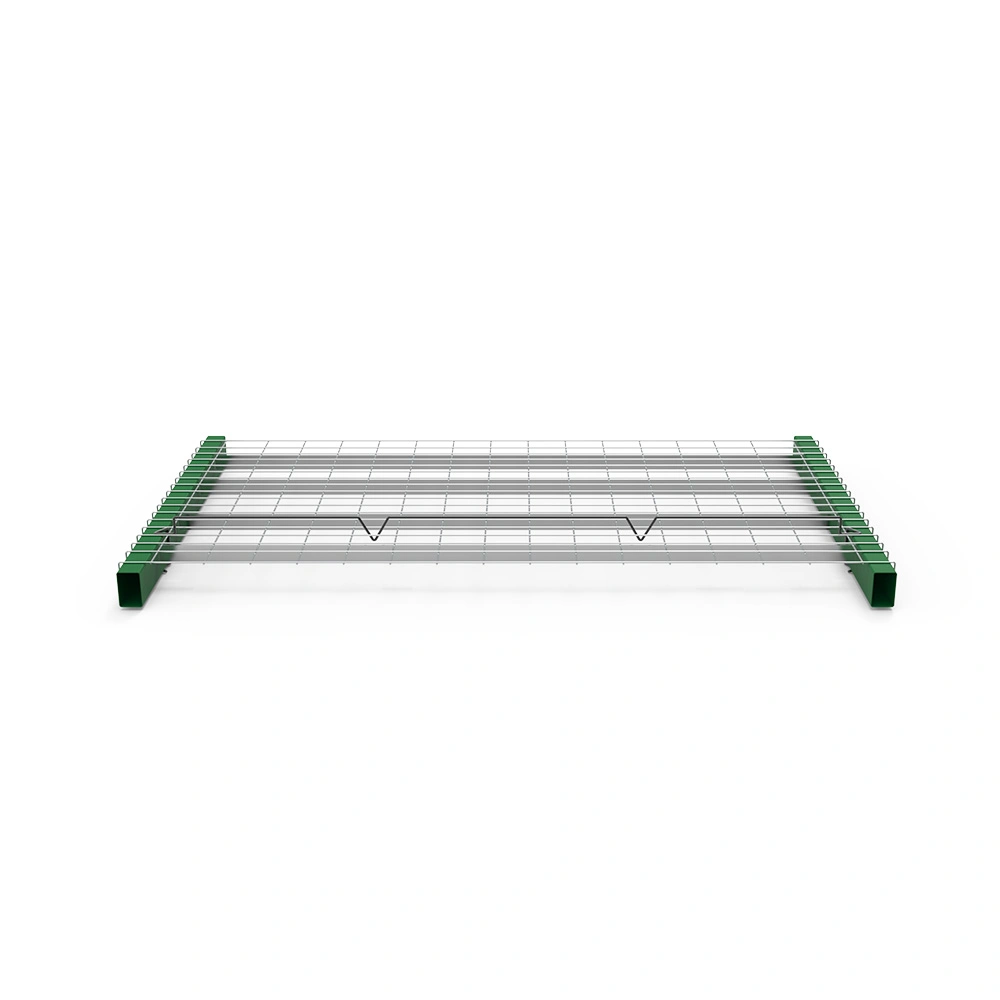

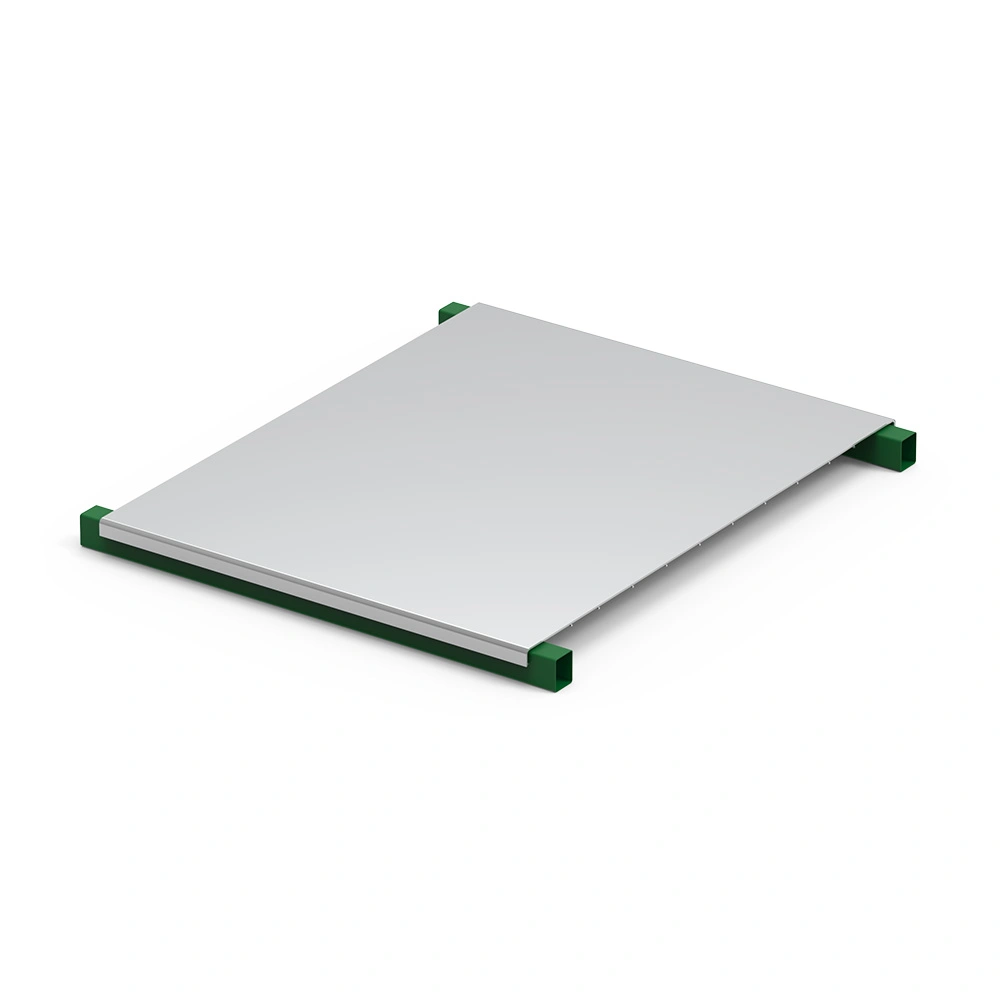

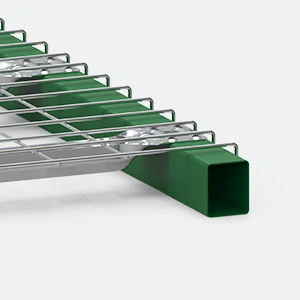

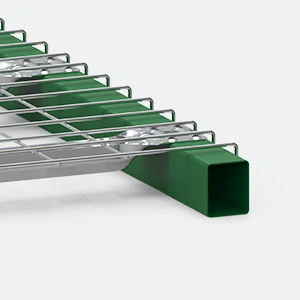

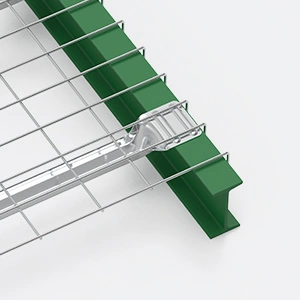

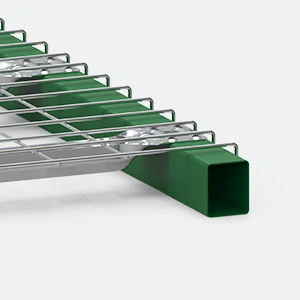

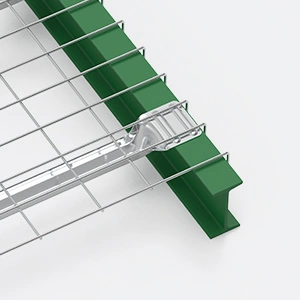

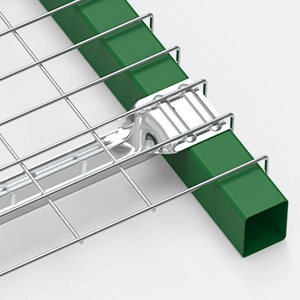

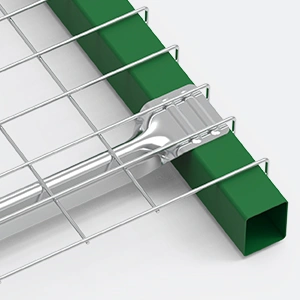

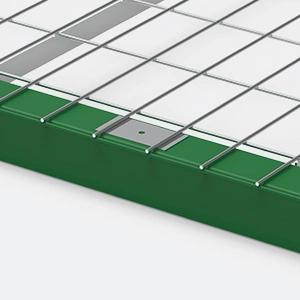

Thanks to the round or flat supports welded to the panel, the Loadex electrowelded mesh decks can support loads for all palletized goods requirements. Produced in both standard and special sizes, they do not require fixing and can be quickly and easily adapted to all requirements.

The wire mesh improves safety and helps to maximise storage space for any logistics solution fitted with a beam racking system. It improves the performance of fire sprinkler systems and ensures better light dispersion, reducing areas of shadow. In addition to allowing light to permeate, smoke to rise and water to fall in the event of a fire, mesh panels do not add to the installation’s "fire load" to the installation, making logistics facilities safer.

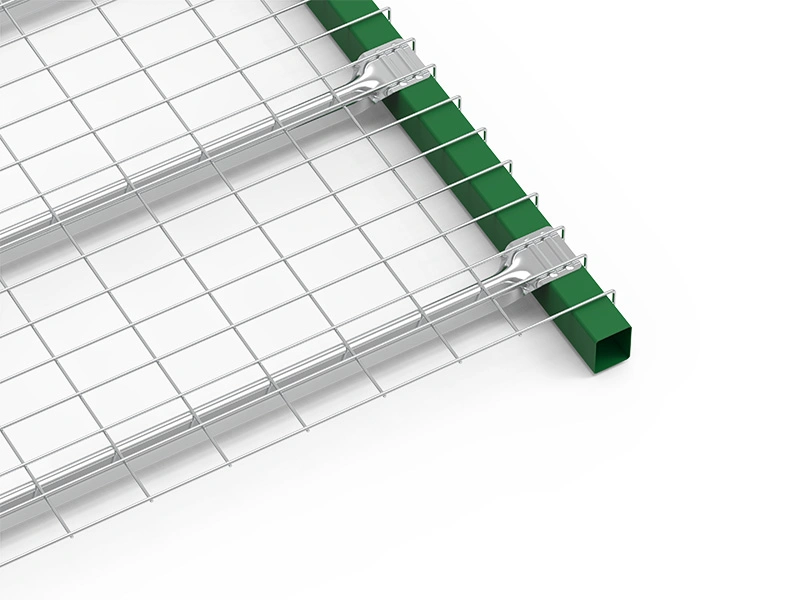

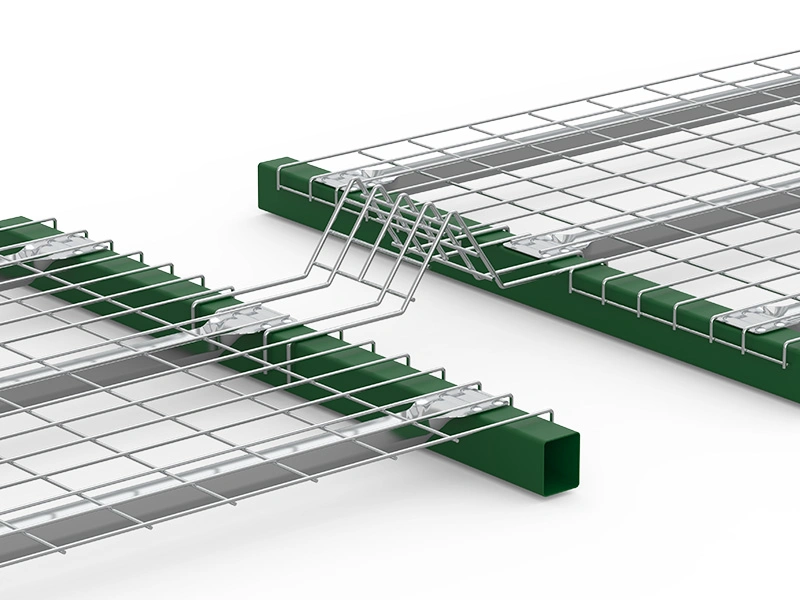

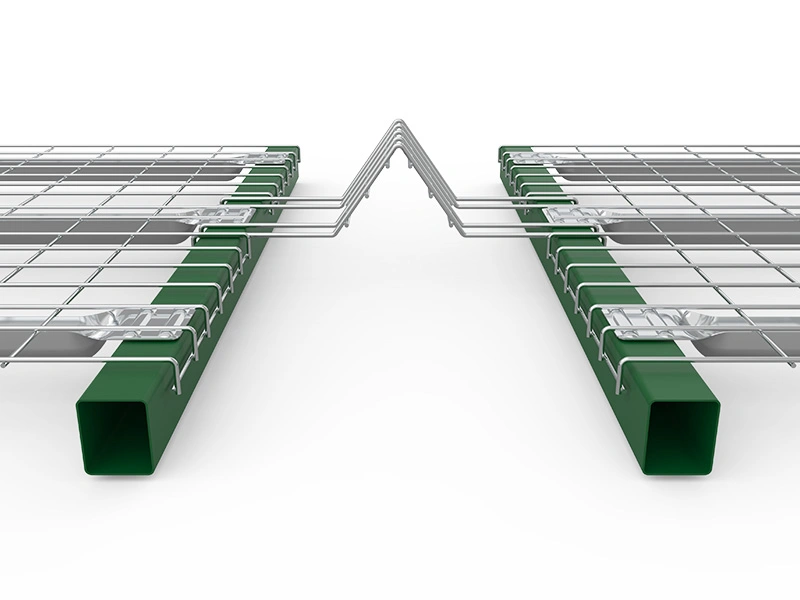

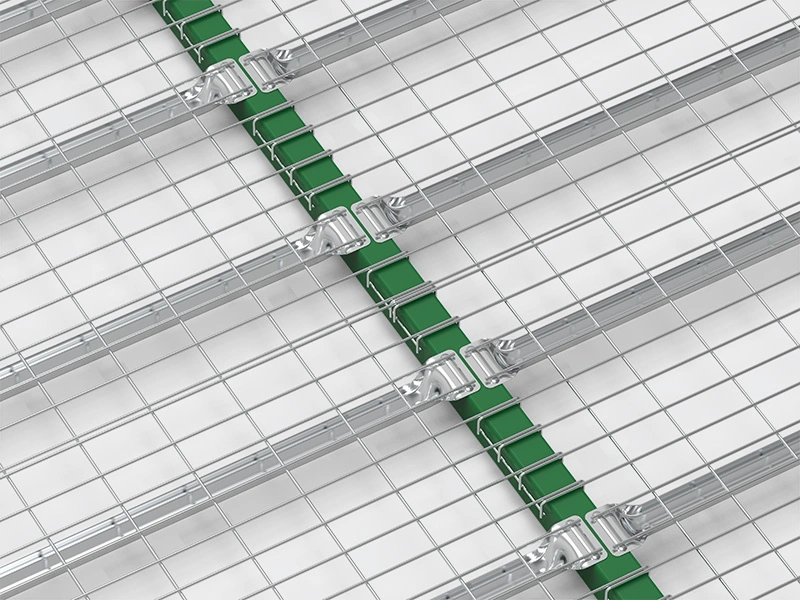

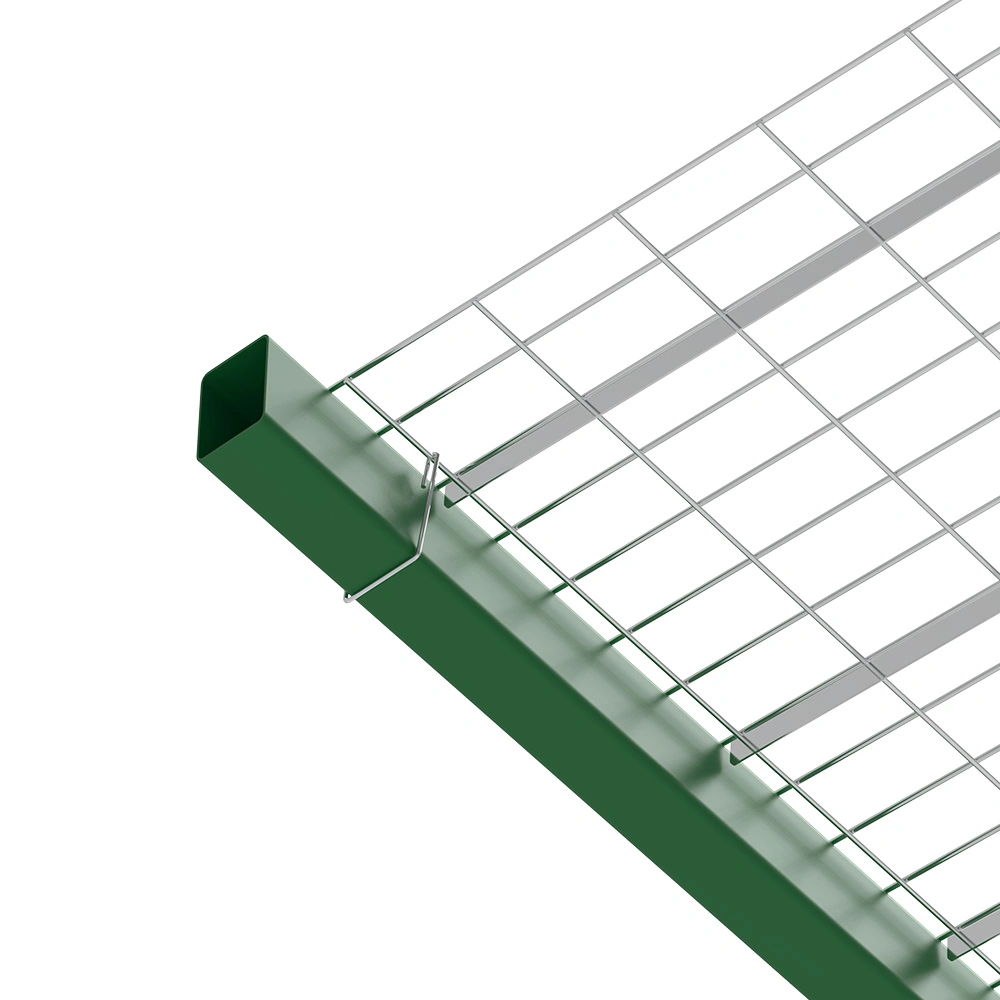

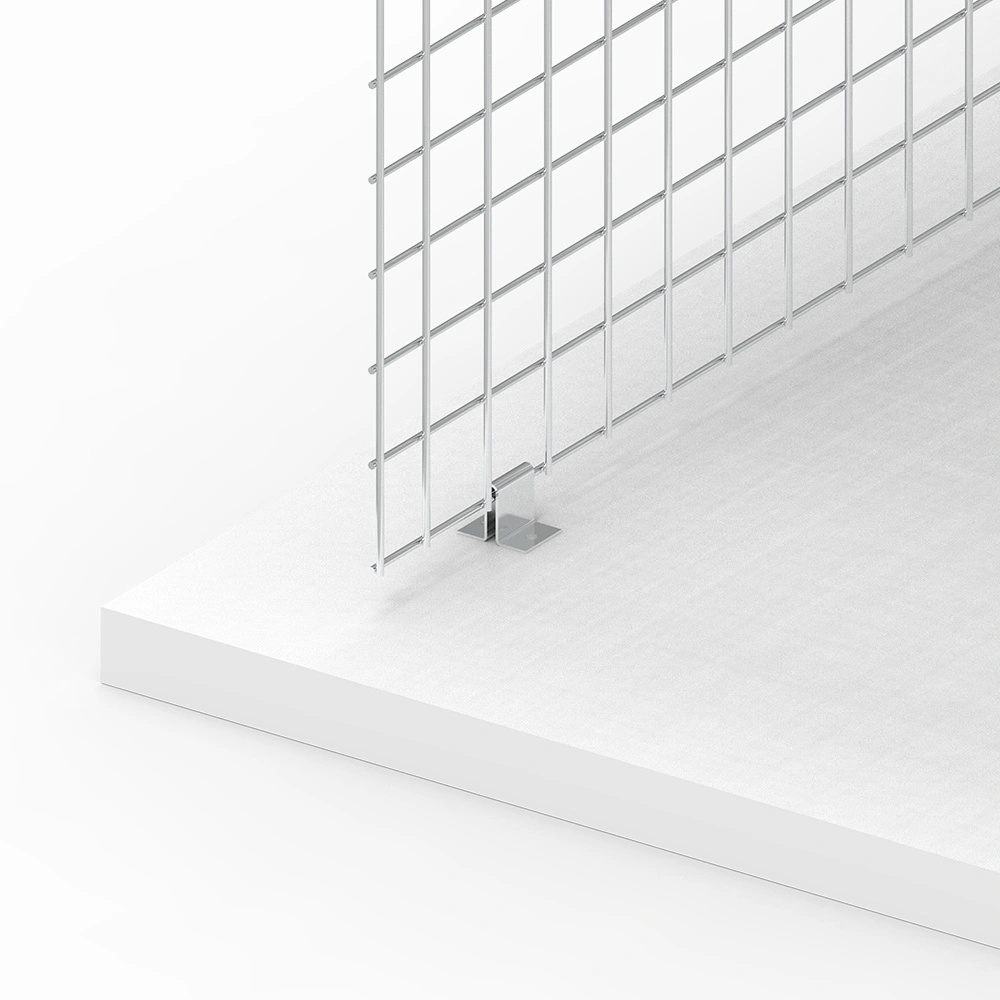

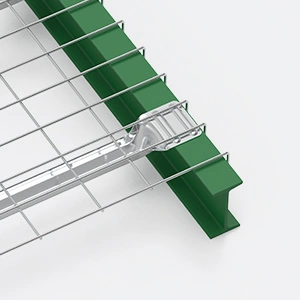

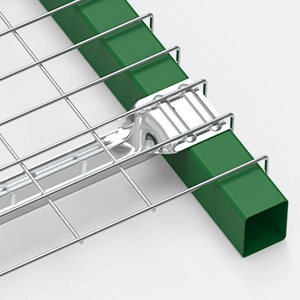

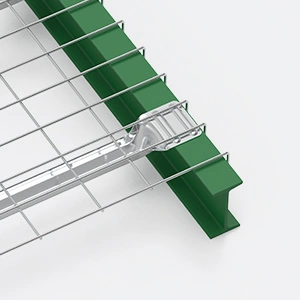

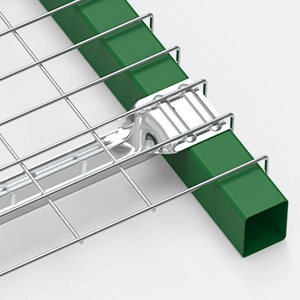

The electrowelded mesh panel is easy to install and requires no tools because the side edges of the panel fit perfectly between the beams of the racking.

The Loadex panel is the best option in terms of load capacity/cost ratio thanks to its electrowelded stiffeners and the perfectly optimized geometry to deliver the maximum load capacity which make it particularly suitable for the use of pallets. Pallets do not need to be perfectly positioned on the beams or to be completely stable.

Show more

Hide

Where do you want to begin your selection?

standard

Choose

by panel.

The mesh decks for pallets are available in stock in standard sizes which can be checked in the tables below.

TECHNICAL SPECIFICATIONS

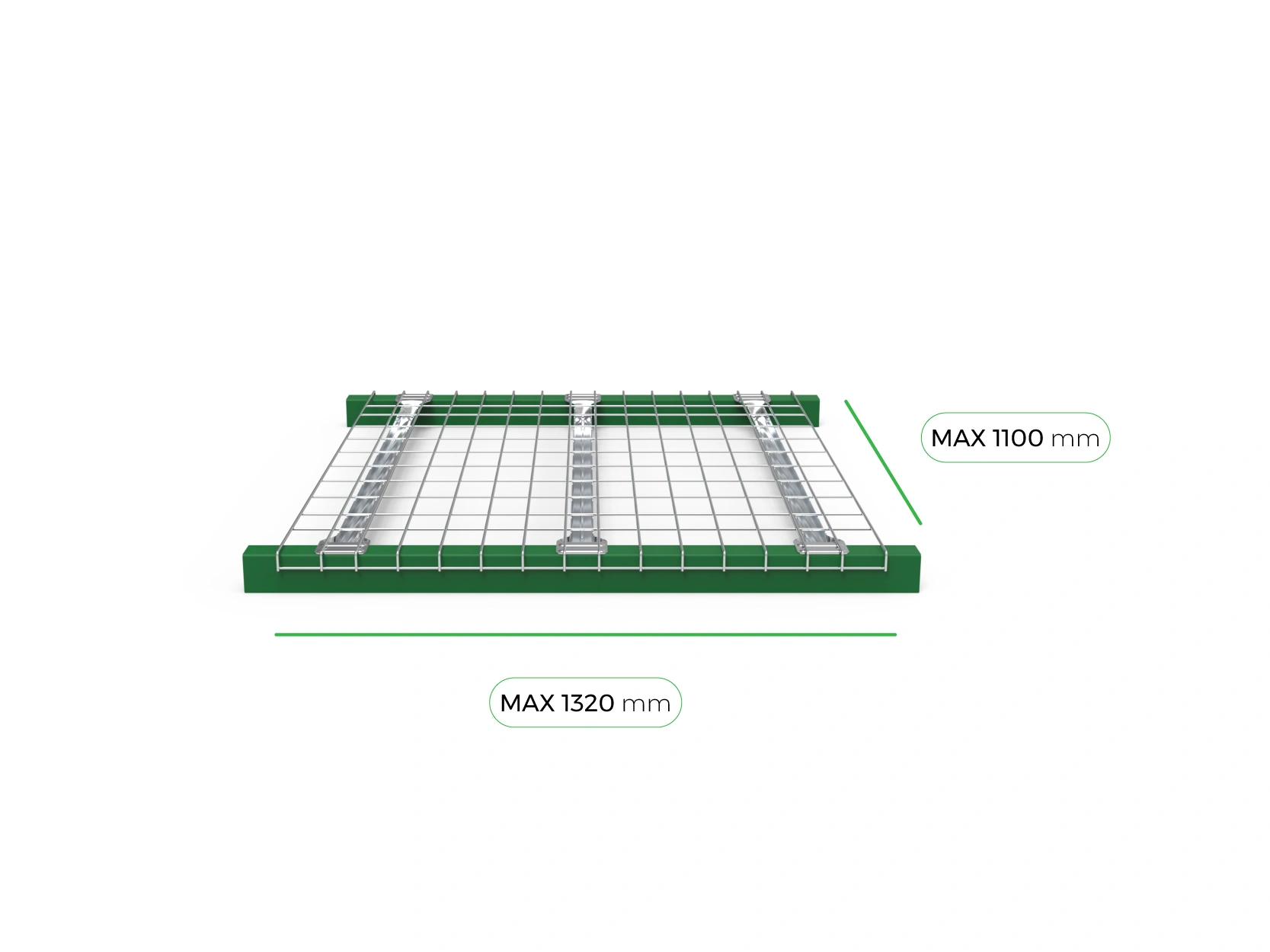

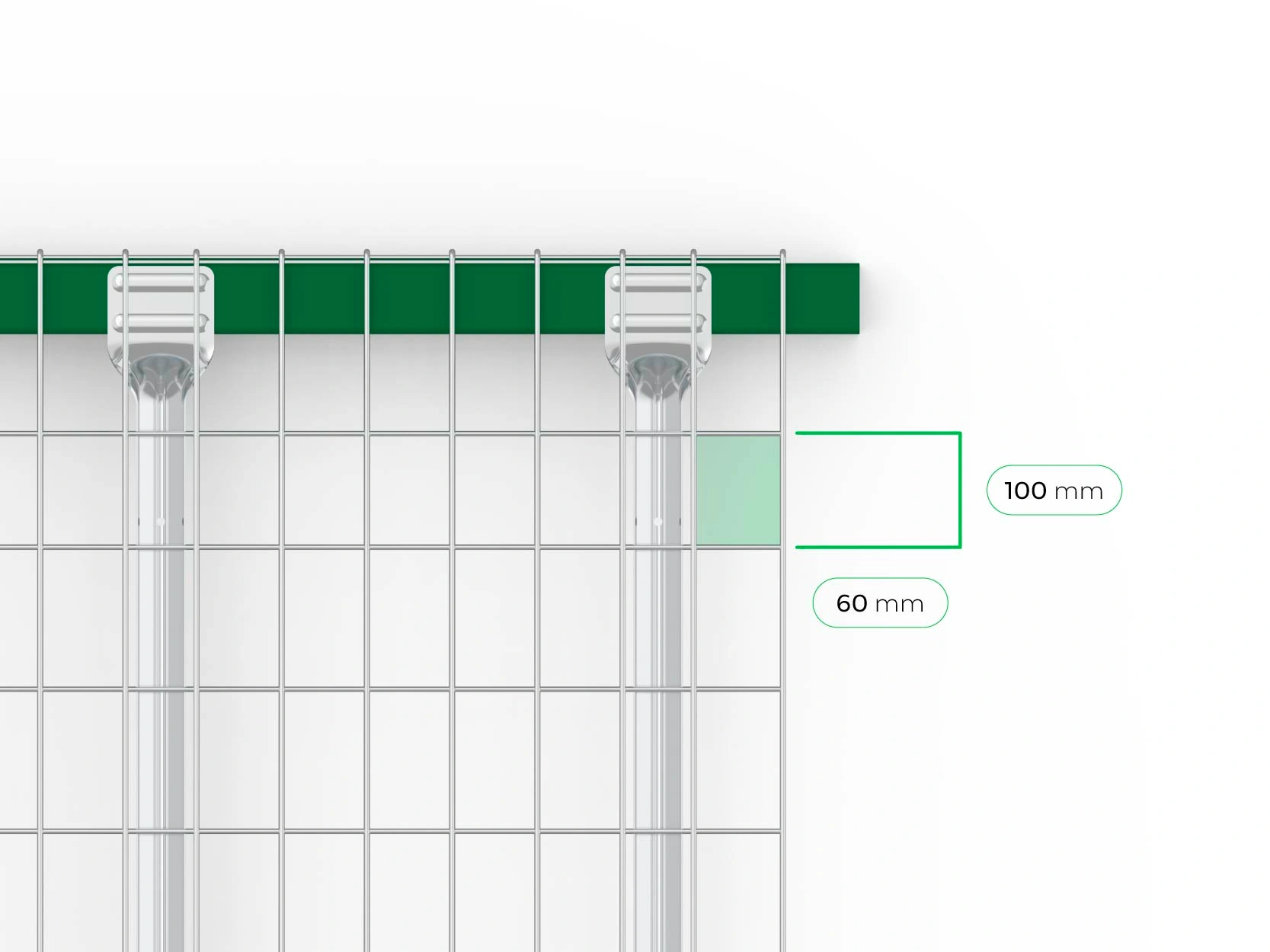

Standard Mesh Size (mm): 60 x 100

Stiffeners: 3, 4, 5 depending on the load

Standard Load (kg): 300kg, 500kg, 800kg, 1500kg

Load footprint: pallet standing on the 2 beams, pallet standing on at least one beam or uniformly distributed

Finish: pre-galvanized, painted, BZP and HDG

Standard crosspiece (mm): 50 mm

Show more

Hide

Standard Mesh Size (mm): 60 x 100

Stiffeners: 3, 4, 5 depending on the load

Standard Load (kg): 300kg, 500kg, 800kg, 1500kg

Load footprint: pallet standing on the 2 beams, pallet standing on at least one beam or uniformly distributed

Finish: pre-galvanized, painted, BZP and HDG

Standard crosspiece (mm): 50 mm

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1100 | 60 × 125 | 3 Omega 75 | 300 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 1090 × 1000 | 60 × 100 | 3 Omega 75 | 500 |

| 1090 × 1000 | 60 × 100 | 3 Omega 75 | 800 |

| 1090 × 1000 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 1090 × 1050 | 60 × 100 | 3 Omega 75 | 500 |

| 1090 × 1050 | 60 × 100 | 3 Omega 75 | 800 |

| 1090 × 1050 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 1090 × 1100 | 60 × 100 | 3 Omega 75 | 500 |

| 1090 × 1100 | 60 × 100 | 3 Omega 75 | 800 |

| 1090 × 1100 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 1320 × 1100 | 60 × 100 | 4 Omega 75 | 500 |

| 1320 × 1100 | 60 × 100 | 4 Omega 75 | 800 |

| 1320 × 1100 | 60 × 100 | 4 Omega 75 | 1000 |

Features

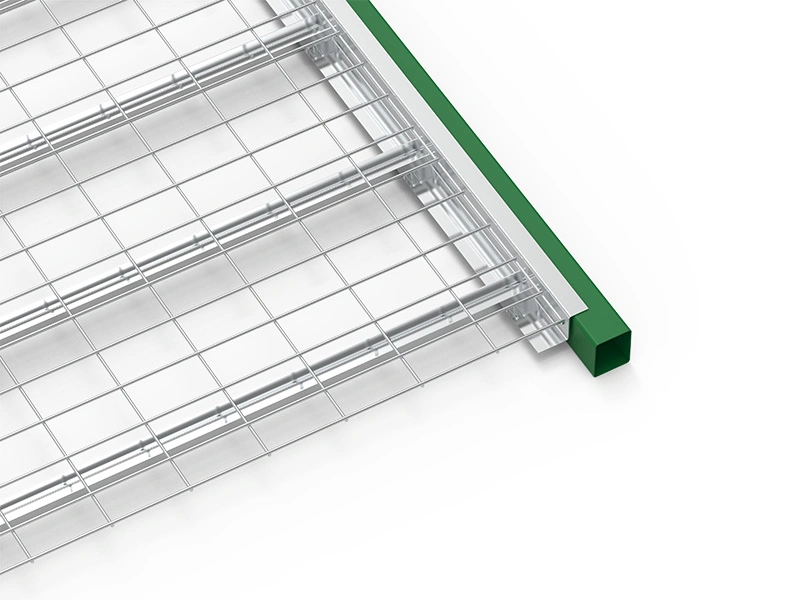

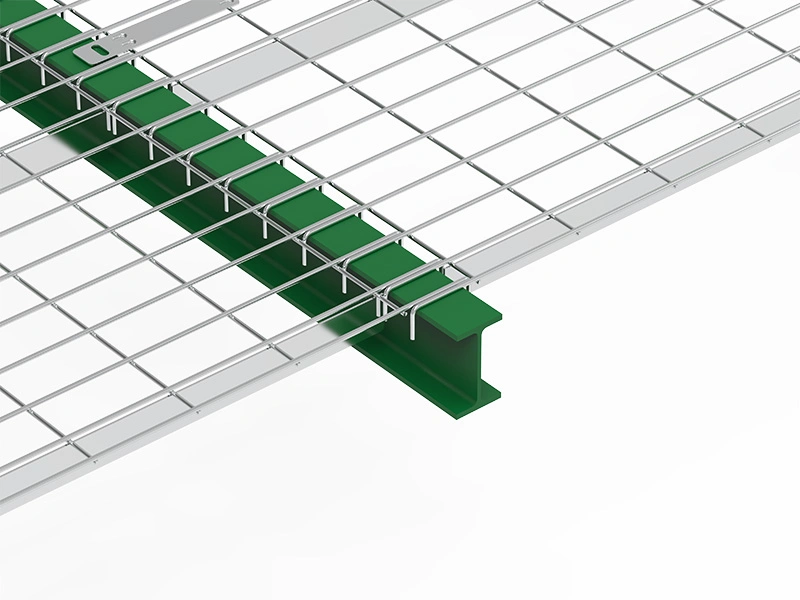

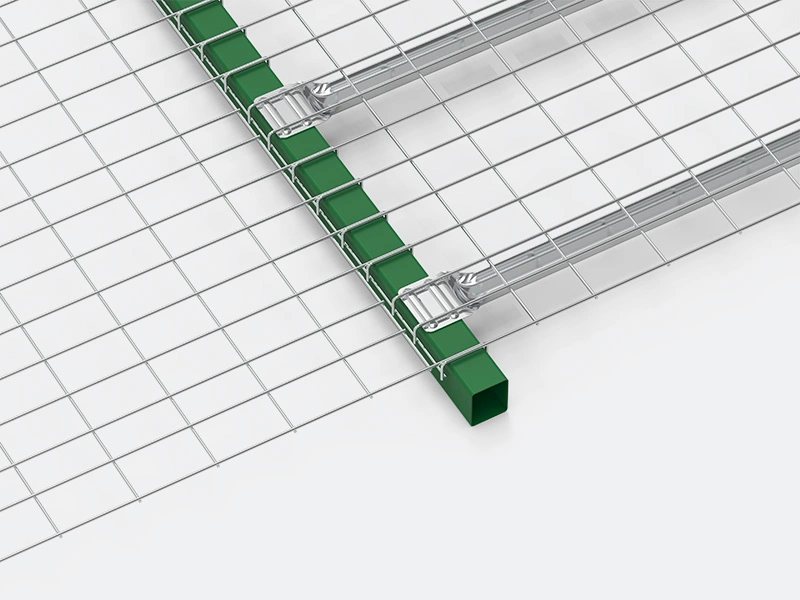

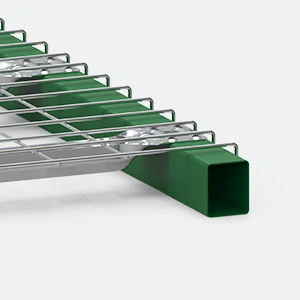

BOX BEAM

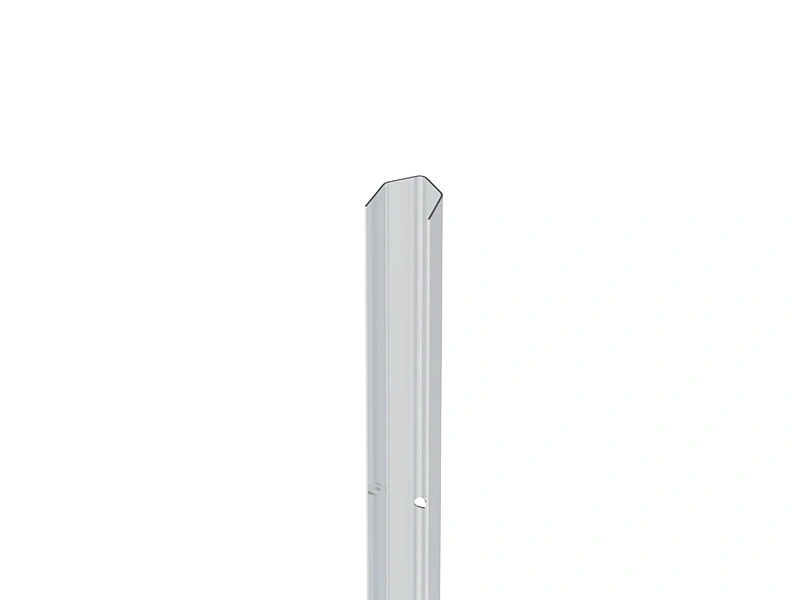

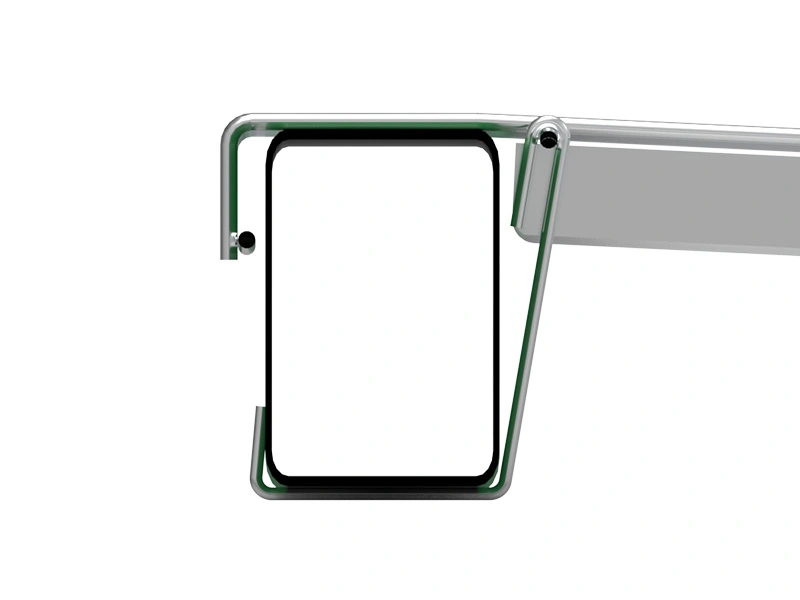

STRUCTURAL PROFILES

FLARED CHANNEL

BETWEEN THE BEAMS (LOAD PARALLEL TO THE BEAMS)

STANDING ON AT LEAST ONE BEAM

STANDING ON BOTH BEAMS (LOAD PERPENDICULAR TO THE BEAMS)

CUSTOM POINT LOADS

ROUNDED EDGES FLARED CHANNEL STIFFENER

PRE-GALVANIZED

standard

Choose

by racking.

The mesh decks for pallets are available in stock in standard sizes which can be checked in the tables below.

TECHNICAL SPECIFICATIONS

Standard Mesh Size (mm): 60 x 100

Stiffeners: 3, 4, 5 depending on the load

Standard Load (kg): 300kg, 500kg, 800kg, 1500kg

Load footprint: pallet standing on the 2 beams, pallet standing on at least one beam or uniformly distributed

Finish: pre-galvanized, painted, BZP and HDG

Standard crosspiece (mm): 50 mm

Show more

Hide

Standard Mesh Size (mm): 60 x 100

Stiffeners: 3, 4, 5 depending on the load

Standard Load (kg): 300kg, 500kg, 800kg, 1500kg

Load footprint: pallet standing on the 2 beams, pallet standing on at least one beam or uniformly distributed

Finish: pre-galvanized, painted, BZP and HDG

Standard crosspiece (mm): 50 mm

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1100 | 60 × 125 | 3 Omega 75 | 300 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 1000 |

| 1320 × 1100 | 60 × 100 | 3 Omega 75 | 500 |

| 1320 × 1100 | 60 × 100 | 3 Omega 75 | 800 |

| 1320 × 1100 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 1090 × 1000 | 60 × 100 | 3 Omega 75 | 500 |

| 1090 × 1000 | 60 × 100 | 3 Omega 75 | 800 |

| 1090 × 1000 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 1090 × 1050 | 60 × 100 | 3 Omega 75 | 500 |

| 1090 × 1050 | 60 × 100 | 3 Omega 75 | 800 |

| 1090 × 1050 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 1090 × 1100 | 60 × 100 | 3 Omega 75 | 500 |

| 1090 × 1100 | 60 × 100 | 3 Omega 75 | 800 |

| 1090 × 1100 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1100 | 60 × 125 | 3 Omega 75 | 300 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 1000 |

Features

BOX BEAM

STRUCTURAL PROFILES

FLARED CHANNEL

BETWEEN THE BEAMS (LOAD PARALLEL TO THE BEAMS)

STANDING ON AT LEAST ONE BEAM

STANDING ON BOTH BEAMS (LOAD PERPENDICULAR TO THE BEAMS)

CUSTOM POINT LOADS

ROUNDED EDGES FLARED CHANNEL STIFFENER

PRE-GALVANIZED

standard

Choose

by pallet.

The mesh decks for pallets are available in stock in standard sizes which can be checked in the tables below.

TECHNICAL SPECIFICATIONS

Standard Mesh Size (mm): 60 x 100

Stiffeners: 3, 4, 5 depending on the load

Standard Load (kg): 300kg, 500kg, 800kg, 1500kg

Load footprint: pallet standing on the 2 beams, pallet standing on at least one beam or uniformly distributed

Finish: pre-galvanized, painted, BZP and HDG

Standard crosspiece (mm): 50 mm

Show more

Hide

Standard Mesh Size (mm): 60 x 100

Stiffeners: 3, 4, 5 depending on the load

Standard Load (kg): 300kg, 500kg, 800kg, 1500kg

Load footprint: pallet standing on the 2 beams, pallet standing on at least one beam or uniformly distributed

Finish: pre-galvanized, painted, BZP and HDG

Standard crosspiece (mm): 50 mm

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 1000 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 1000 |

| 880 × 1100 | 60 × 125 | 3 Omega 75 | 300 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 1090 × 1000 | 60 × 100 | 3 Omega 75 | 500 |

| 1090 × 1000 | 60 × 100 | 3 Omega 75 | 800 |

| 1090 × 1000 | 60 × 100 | 3 Omega 75 | 1000 |

| 1090 × 1050 | 60 × 100 | 3 Omega 75 | 500 |

| 1090 × 1050 | 60 × 100 | 3 Omega 75 | 800 |

| 1090 × 1050 | 60 × 100 | 3 Omega 75 | 1000 |

| 1090 × 1100 | 60 × 100 | 3 Omega 75 | 500 |

| 1090 × 1100 | 60 × 100 | 3 Omega 75 | 800 |

| 1090 × 1100 | 60 × 100 | 3 Omega 75 | 1000 |

| 1320 × 1100 | 60 × 100 | 3 Omega 75 | 500 |

| 1320 × 1100 | 60 × 100 | 3 Omega 75 | 800 |

| 1320 × 1100 | 60 × 100 | 3 Omega 75 | 1000 |

| Panel dimensions (mm) | Mesh deck pitch (mm) | Stiffener type | kg/UDL - UR |

|---|---|---|---|

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1000 | 60 × 100 | 3 Omega 75 | 1000 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1050 | 60 × 100 | 3 Omega 75 | 1000 |

| 880 × 1100 | 60 × 125 | 3 Omega 75 | 300 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 500 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 800 |

| 880 × 1100 | 60 × 100 | 3 Omega 75 | 1000 |

Features

BOX BEAM

STRUCTURAL PROFILES

FLARED CHANNEL

BETWEEN THE BEAMS (LOAD PARALLEL TO THE BEAMS)

STANDING ON AT LEAST ONE BEAM

STANDING ON BOTH BEAMS (LOAD PERPENDICULAR TO THE BEAMS)

CUSTOM POINT LOADS

ROUNDED EDGES FLARED CHANNEL STIFFENER

PRE-GALVANIZED

custom

panel.

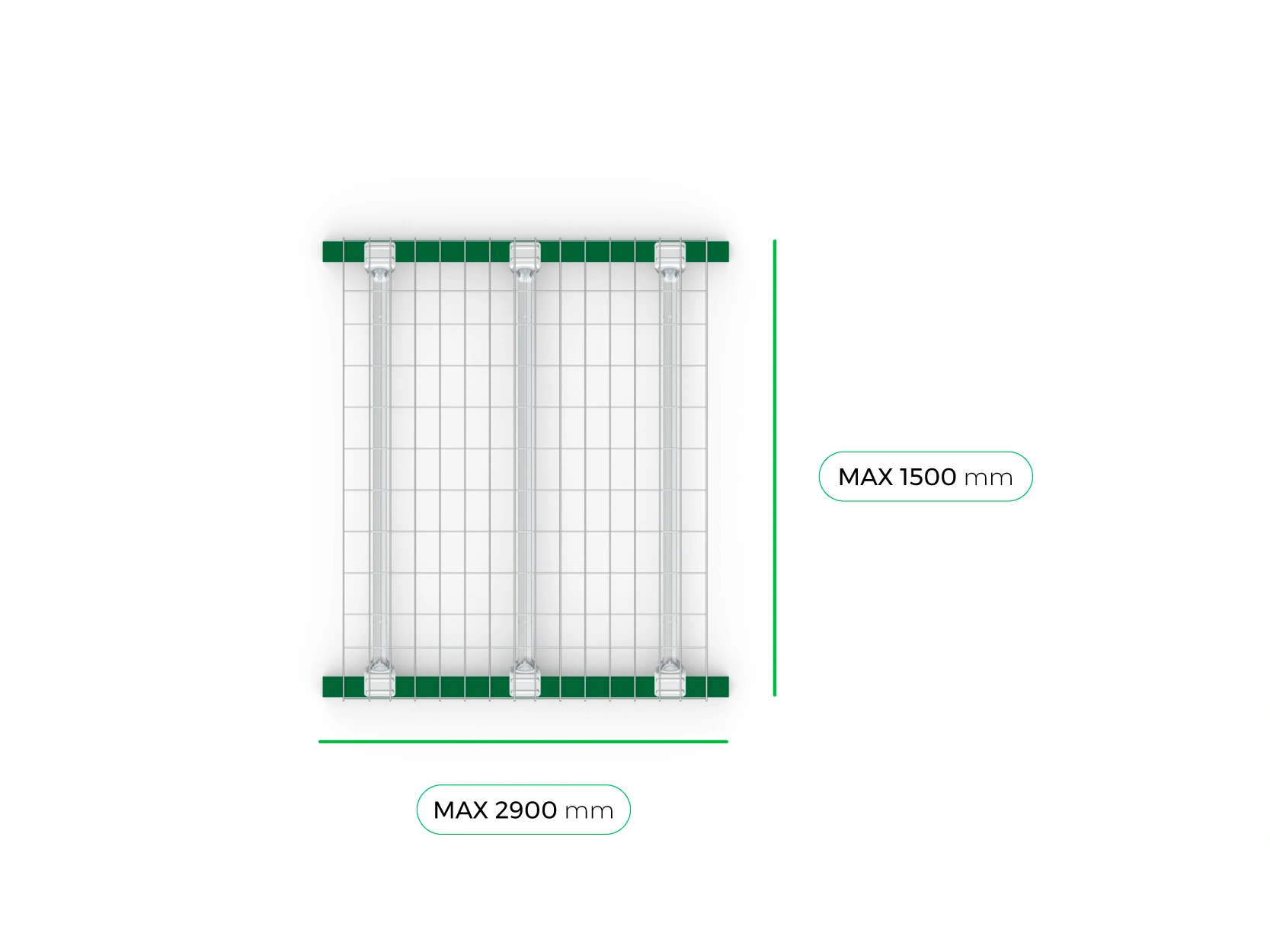

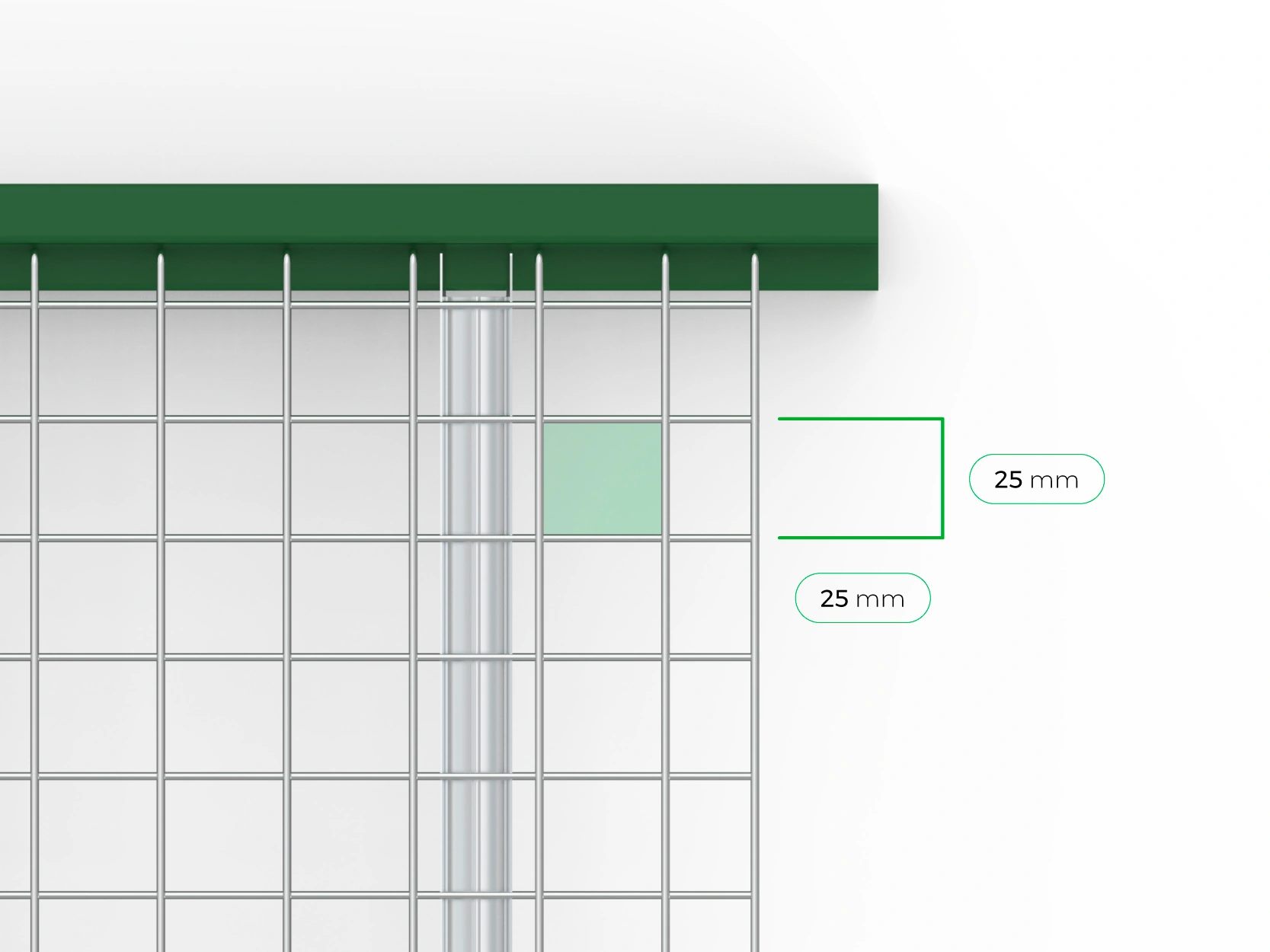

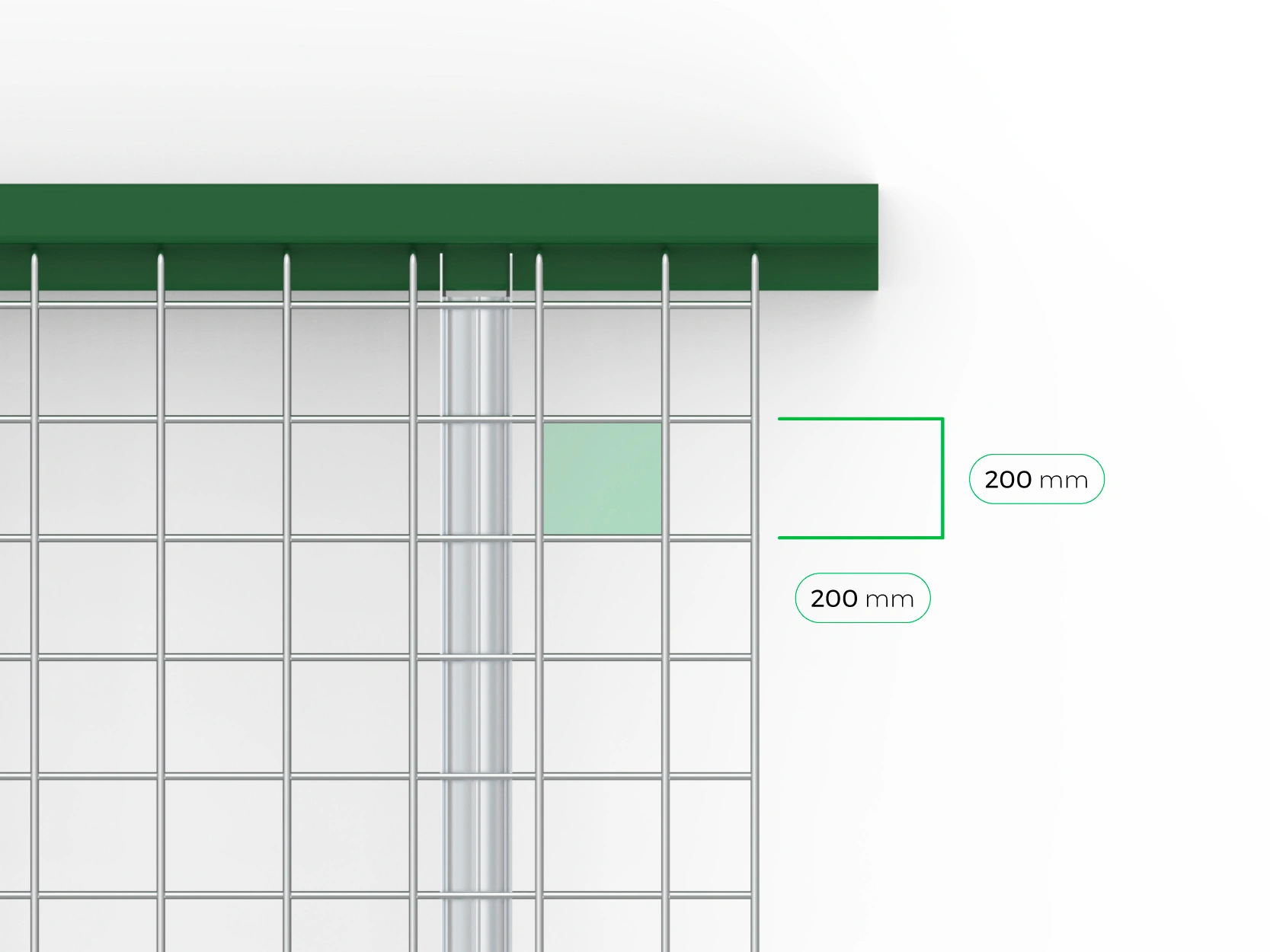

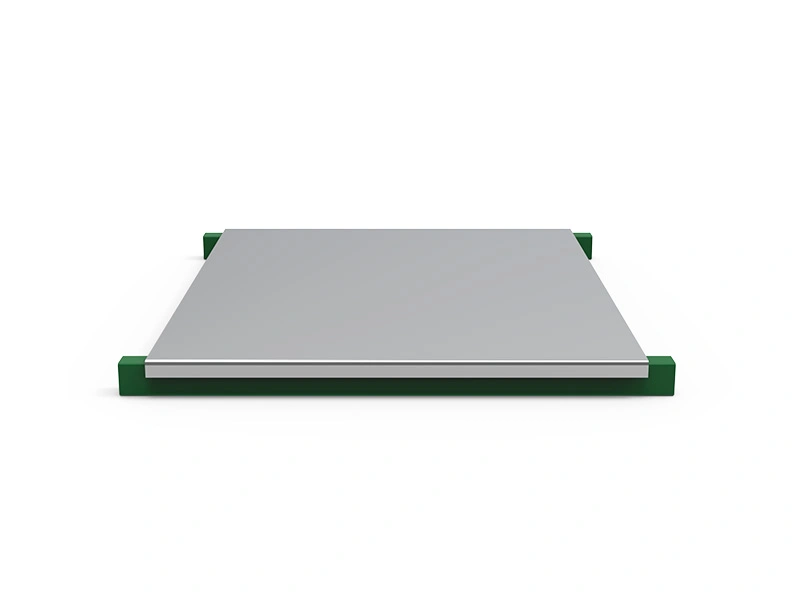

We offer a wide range of custom products with panels adapted to meet the needs of the customer.

TECHNICAL SPECIFICATIONS

Custom Mesh Size (mm): from 25 x 25 to 200 x 200 mm

Stiffeners: 3, 4, 5 depending on the load

Custom Load (Kg): according to load requirements

Load footprint: pallet standing on the 2 beams, pallet standing on at least one beam or uniformly distributed

Finish: pre-galvanized, painted, BZP and HDG

Standard crosspiece (mm): 50 mm

Show more

Hide

Custom Mesh Size (mm): from 25 x 25 to 200 x 200 mm

Stiffeners: 3, 4, 5 depending on the load

Custom Load (Kg): according to load requirements

Load footprint: pallet standing on the 2 beams, pallet standing on at least one beam or uniformly distributed

Finish: pre-galvanized, painted, BZP and HDG

Standard crosspiece (mm): 50 mm

selectable features

MESH DECK WITH INVERTED FLARED CHANNEL STIFFENER

Option to produce inverted stiffeners based on the customer’s requirements....

Data sheet

MESH DECK WITH HALF-MOON STIFFENER

Panel suitable for medium loads for the type of pallet...

Data sheet

DOUBLE DEPTH MESH DECK - FLARED CHANNEL STIFFENER

We have machinery for producing double/triple depth continuous panels....

Data sheet

HIGH Z-MESH DECK WITH HALF-MOON STIFFENER

Panel designed for medium-light loads, where the full width of...

Data sheet

INTERMEDIATE MESH DECK WITH STIFFENER

We have machinery for producing double/triple depth continuous panels....

Data sheet

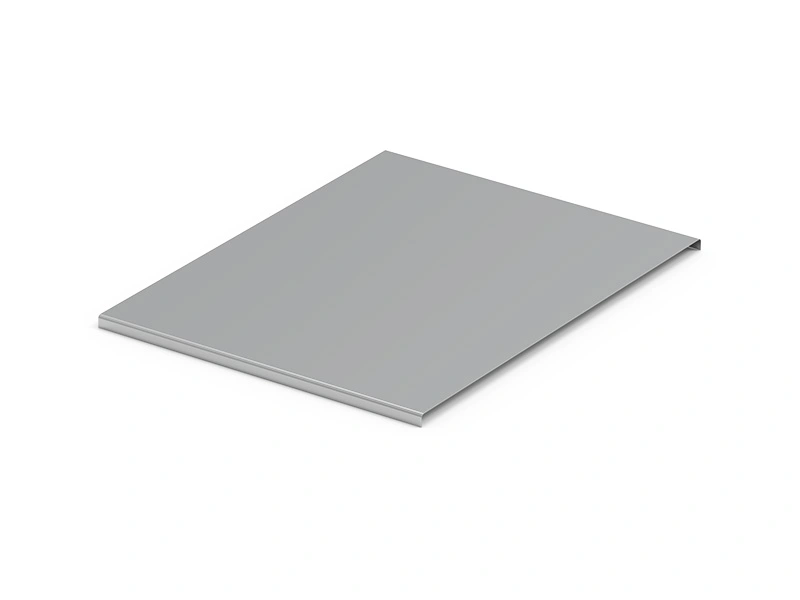

INTERMEDIATE MESH DECK WITHOUT STIFFENER

Option to produce intermediate panels for triple depth, which fit...

Data sheet

Features

BOX BEAM

STRUCTURAL PROFILES

FLARED CHANNEL

INVERTED FLARED CHANNEL

BETWEEN THE BEAMS (LOAD PARALLEL TO THE BEAMS)

STANDING ON AT LEAST ONE BEAM

STANDING ON BOTH BEAMS (LOAD PERPENDICULAR TO THE BEAMS)

CUSTOM POINT LOADS

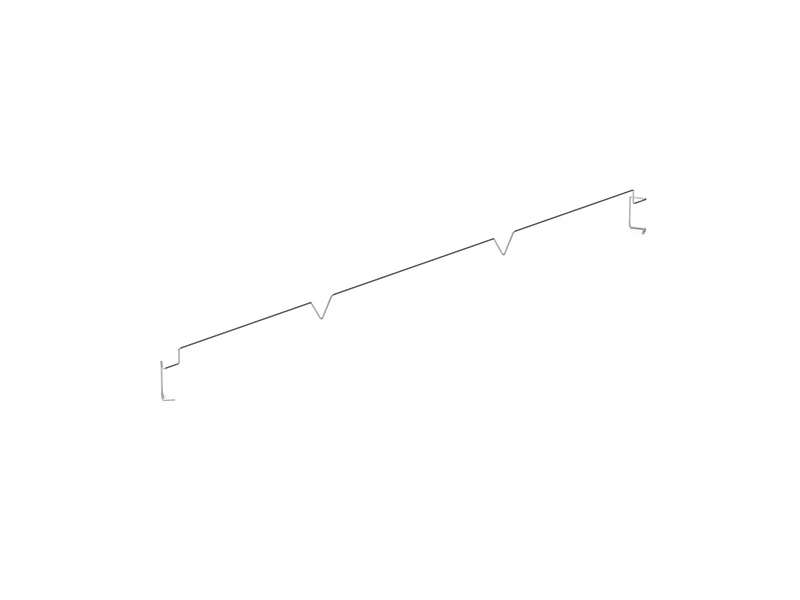

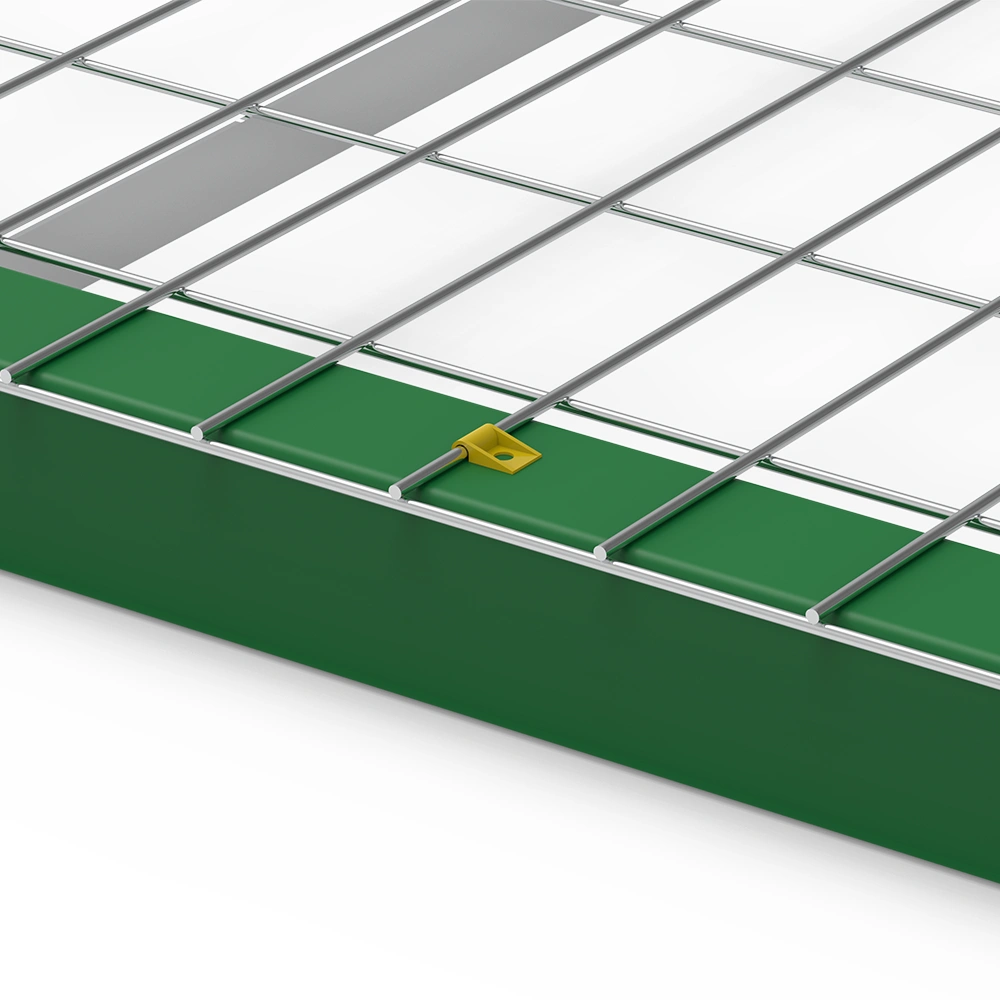

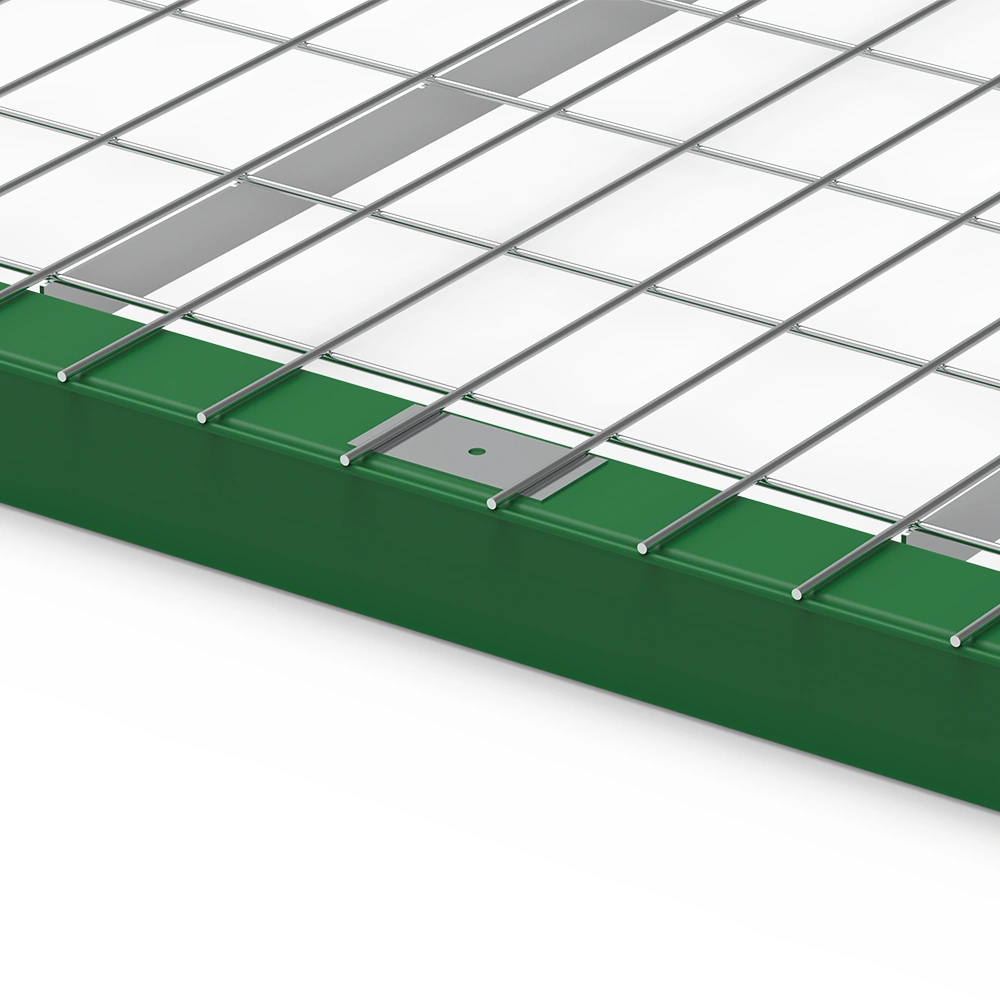

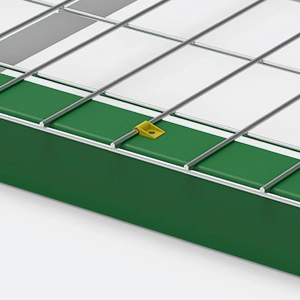

Safe Edge

Chamfered wire

45° cut wire

Chamfered reinforcement

ROUNDED EDGES STIFFENER

Rounded edges flared channel stiffener

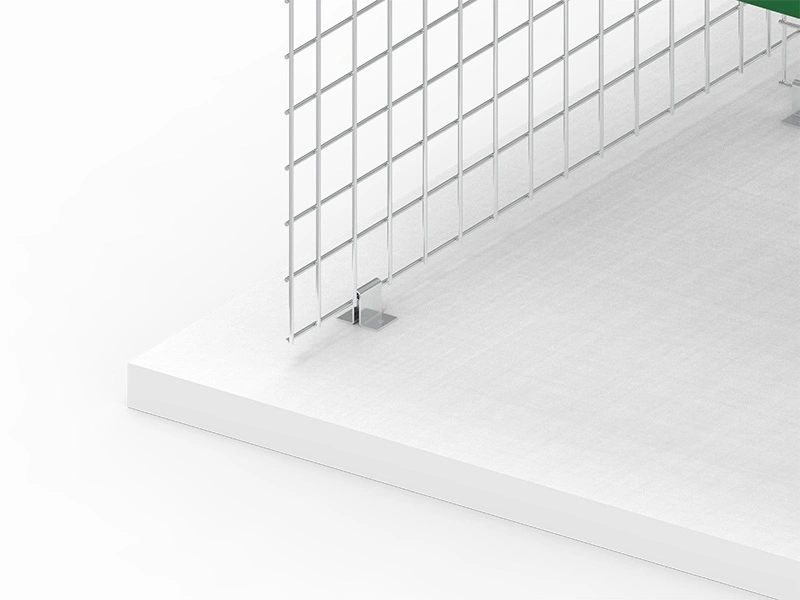

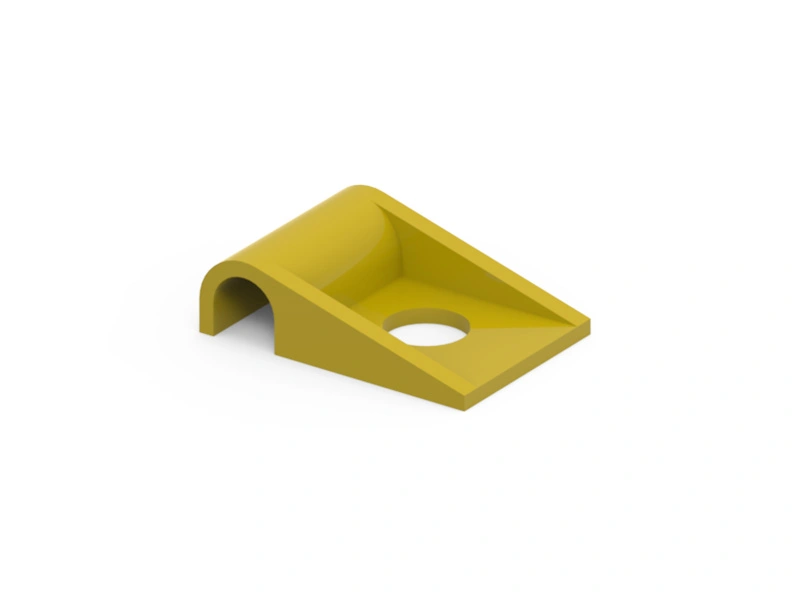

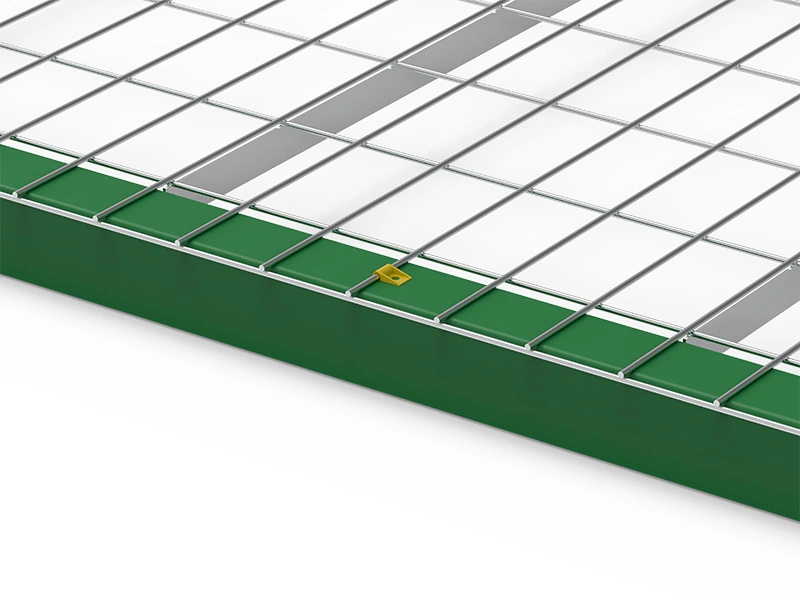

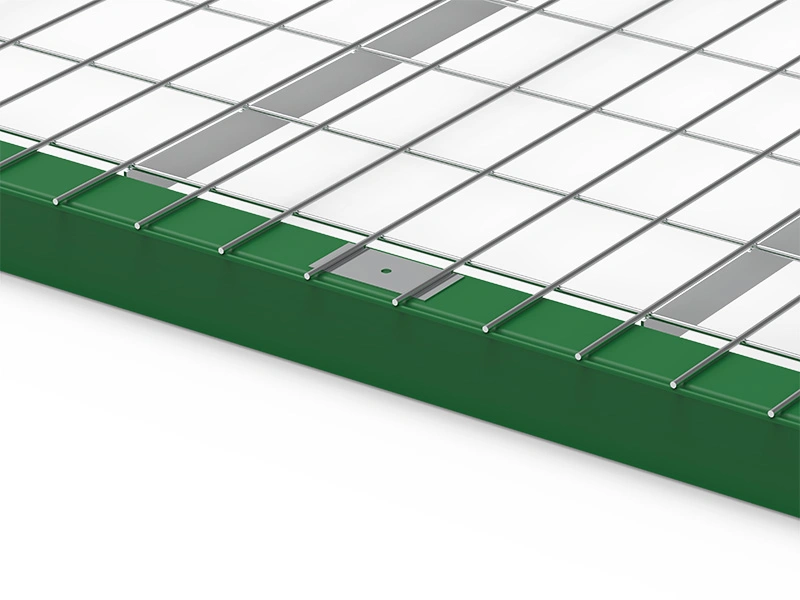

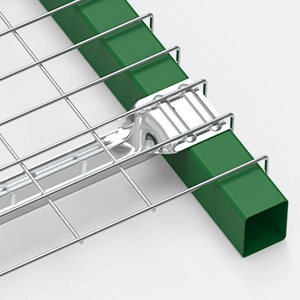

Panel fixing solutions (bracket)

Panel fixing solutions (clip)

PRE-GALVANIZED

Electrozincplated

Hot-dip galvanized

Painted

Related accessories